Results 2020: key events of TAIF Group in the past year

Anniversary in the face of COVID-19 pandemic, new appointments, success in the implementation of large-scale projects and new plans

The past 2020 year was rich in anniversaries: the republic celebrated the 100th anniversary of the formation of the Tatar ASSR, Russia celebrated the 75th anniversary of the Victory in the Great Patriotic War, and TAIF — 30 years since the formation of Kazan VTNPO — the company with which one of the largest industrial and financial groups in Russia begins its history. How will the year 2020 be remembered? Read the details in the material of Realnoe Vremya.

30 years with the republic

TAIF celebrated its 30th anniversary without spectacular celebrations or lavish banquets.

In the autumn of 1990, during the dissolution of the USSR, which reshaped the geopolitical map of the world and the balance of power, in the midst of the perestroika period when everything was changing in Russia: political and economic system, the perception of the world and the understanding of each person's own place in these processes, when, in fact, the centralised system of the orders and sales of finished products in the country, built by the state, ceased to exist, there was a deficit of absolutely everything, including the most necessary, Kazan VTNPO foreign trade organisation was established in the capital of Tatarstan. It took on the task of supplying the population with essential products — food, clothing, fuel and lubricants. The newly formed company was headed by young and little-known Albert Shigabutdinov.

A couple of years later, the company took on the mission of helping local producers restore the ties destroyed by the fall of the centralised system of state procurement — helping to organise the supply of raw materials and the sale of finished products. Later, they built an effective supply chain for equipment. Then they began to search for the technologies and investments necessary for further development of Tatarstan's industry to implement large-scale plans.

On Cosmonautics Day, April 12, 1995, a modest article was published in Respublika Tatarstan newspaper, which read: “Yesterday in the Kremlin, President Mintimer Shaimiev received Chairperson of the Board of Directors of Com-Liz-Inc. D. Mckennis (USA), President of NKS Trading Inc. A. Friedman (USA), Deputy Prime Minister, Chairman of the State Committee for State Property Management of the Republic of Tatarstan F.R. Gazizullin, Director General of the Kazan foreign trade research and production association A.K. Shigabutdinov, who told that they had reached an agreement to create an international investment company to attract capital and invest it in the economy of our republic.”

Already on August 10, 1995, on the basis of Kazan VTNPO, TAIF OJSC was created, later transformed into TAIF JSC and became the parent company of one of the largest multi-profile non-governmental companies in Russia.

Already at the beginning of its work, TAIF actively advocated the preservation and development of the industrial potential of the republic. Not limited to appeals, the company itself actively invested in those areas of the economy, the absence or underdevelopment of which seriously hindered market transformations in the republic. The company became engaged in creating the market of modern telecommunications, including multimedia services — it launched mobile and fixed-line communication projects, created terrestrial and satellite television. During the reconstruction and construction of the primary oil processing plant, it became obvious to TAIF-NK that there were no modern construction capacities in Tatarstan. And they were created. Faced with a shortage of qualified personnel, TAIF organised the training of specialists abroad. Later, realising that it was impossible to retain employees without providing them with decent living conditions, TAIF Group were among the first in Russia to invest in the implementation of housing construction programmes, as well as in the renewal of the healthcare system, social security, sports development and the creation of comfortable urban spaces.

Oil and gas processing, chemistry and petrochemistry, power engineering, refuelling business, construction, communications and media, entertainment, social programmes... Probably, in the republic, there is not a single industry, sector or industry in which TAIF would not take a direct and active part.

TAIF Group's companies — system-forming organisations of the economy and fuel and energy sector of Russia

In March 2020, the government commission for improving the sustainability of the Russian economy announced a new list of 646 system-forming organisations. Among them, 17 are from Tatarstan, where one of the first lines is taken by the parent company of the group — TAIF JSC.

A little later, in April, the Russian ministry of energy published its list of system-forming organisations in the fuel and energy sector.

“The list includes organisations by approved criteria and procedure, including the dominant position of the organisation in the market of a certain product, the development and implementation of critical technologies and critical software products, information security, the provision of services for the development and operation of state information systems. The final document includes objects belonging to the 10 main sub-sectors of the fuel and energy sector," the website of the Russian ministry of energy reports. In total, the list includes 97 organisations, including four key companies of the group — TAIF-NK JSC, Nizhnekamskneftekhim PJSC, Kazanorgsintez PJSC and TGC-16 JSC.

The current state-of-the-art level of production capacities of the Group's enterprises is a timely implementation of the competent investment strategy of the TAIF team, well-coordinated joint work of specialists and company management throughout the Group's activities.

In July 2020, at the final meeting of the board of directors of TAIF JSC, the president of the Republic of Tatarstan for the first time proposed the candidacy of Albert Shigabutdinov, who left the post of Director General of TAIF JSC, to the post of Chairman of the board of directors of the Group's parent company:

“It must be authoritative, experienced, and tough enough person. Therefore, my proposal is to recommend Albert Kashafovich Shigabutdinov as the chairman of the board of directors of TAIF JSC. An energetic, experienced person. I ask you to support the candidate and vote," Rustam Minnikhanov addressed the members of the board of directors of TAIF JSC.

The proposed candidate was supported by the board of directors unanimously.

“Predicting how the world and the economy will continue to develop, taking into account the pandemic, the general political and economic situation in the world… No one is going to take that kind of courage right now. But the decisions that have been made on the company's development until 2030, we have discussed this with specialists, and they can be implemented. Today, the leadership of the republic, the president of Tatarstan, and the president of Russia are doing everything possible to create conditions for enterprises to implement the previously adopted plans. But we are going to realise all of them. If only we had enough strength, time and perseverance. And of course — work, work, work. We will fulfill all our social obligations. The most important is people. If we cannot provide a decent standard of living, wages, and material well-being for all our working people, then it is impossible to achieve results. This is the main goal of the Development Strategy," Albert Shigabutdinov announced the priorities immediately after the election.

Also in 2020, the management of two key companies of the Group changed. At the end of February, with the unanimous decision of the company's shareholders and with the approval of the president of the Republic of Tatarstan, Ayrat Safin was appointed director general of Nizhnekamskneftekhim PJSC. Born and raised in Nizhnekamsk, he began his career in 1997 at Nizhnekamskneftekhim PJSC, where he worked his way up from a locksmith to the head of the department. In 2005, he was invited to Kazan to build a new polycarbonate plant of Kazanorgsintez PJSC. In 2013, he took the position of chief technologist of the Ethylene Plant and in the same year headed this most important production for Kazanorgsintez PJSC and managed it until his appointment as Director General of Nizhnekamskneftekhim PJSC.

“The tasks set by the management and shareholders of TAIF Group, President of the Republic of Tatarstan Rustam Minnikhanov — are to continue the positive development of the enterprise through the implementation of investment projects that are designed until 2030. The goal is to improve the company's economic performance and increase tax payments to the regional and federal budgets. This is strengthening in the field of environment, industrial safety, and continuing to work in the social sphere," Ayrat Safin told the Realnoe Vremya correspondent.

“We expect the new director to multiply and improve all the results that have been achieved at Nizhnekamskneftekhim PJSC. It's difficult when you start with a base that has a significant size. Here, one needs to work two or three times more, show more activity. Ayrat Safin is in the prime of life and will be able to multiply, strengthen all the traditions laid down at Nizhnekamskneftekhim and give impetus to the further development of the company," said Ruslan Shigabutdinov, the director general of TAIF JSC.

Another appointment took place in October. Maksim Novikov, who previously held the position of chief engineer of the company, was appointed director general of TAIF-NK JSC.

He began his work experience in 1999 in the same company as an operator of technological units ELOU-AVT-7 of the oil refinery, then became a shift manager at the same production facility. In 2013, he was promoted to deputy chief engineer of the refinery, and in 2014, he was appointed chief engineer of the refinery. In 2019, he was appointed chief engineer of TAIF-NK JSC.

Maksim Novikov was directly involved in the implementation of a number of major projects for the modernisation of the Nizhnekamsk Oil Refinery, the installation of the polymer-bitumen binder production and packaging unit in the bitumen production shop, as well as the reconstruction and technical re-equipment of the primary oil refining unit — the ELOU-AVT-7 unit, with the connection of the facilities of the Heavy Residue Conversion Complex under construction. Maksim Novikov took part in the elaboration of the scheme and building infrastructure to connect the HRCC. By the way, the construction of the Heavy Residue Conversion Complex was also largely carried out with the participation and direct leadership of Mr Novikov.

Countering the COVID-19 pandemic

A surge in the spread of the new coronavirus, which quickly escalated into the COVID-19 pandemic, shocked the whole world. At the beginning of spring, communication between cities and countries was paralysed. The work of public institutions, large shopping and entertainment centres was suspended for a while, and people found themselves in forced self-isolation. The epidemic that swept the whole world was declared a pandemic. The problem of shortage of personal protective equipment, first of all medical masks, became acute.

Already in March, the president of Tatarstan and the leadership of TAIF Group proposed a way out of this situation. Polymatiz JSC — a subsidiary of Nizhnekamskneftekhim PJSC, part of TAIF Group, one of the four (in addition to Polymatiz, it is the Tatarstan plant of Elastic, Avgol Ross near Tula and Netkanika, Moscow) largest Russian manufacturers of polypropylene non-woven material, the same from which medical masks and disposable protective suits for doctors are made (in addition, it produces nonwoven hygiene and construction materials, which until the pandemic occupied major share in the total production). The specifics of the production technology of nonwovens are such that the company works around the clock. People work in two shifts of 12 hours each — editor's note). The company announced its readiness to multiply the production of the necessary material.

In the shortest possible time, the production of Polymatiz JSC was completely transferred to the production of non-woven materials for medical purposes — sewing disposable masks and protective suits. The volume of production of the material for medical masks and protective suits was increased from the previous 5 tonnes per month (data as of January 2020) to 28 tonnes a day by mid-April. For information: about half a million disposable masks can be made from one tonne of non-woven material. The declared production capacity of Polymatiz JSC is 10,000 tonnes a year.

First of all, the production volumes were increased due to that the company reconfigured all available equipment for the production of medical products and switched to a round-the-clock mode of operation. As Radik Yarullin, the director of Polymatiz JSC, told in an interview with Realnoe Vremya, the material never stayed long in the warehouses — it was immediately sent to customers, both large companies and individuals who organised the production of masks.

“The average price for our nonwoven fabric remained at the same level. We are not trying to make money on the pandemic but continue to do our job honestly, increasing the volume of production of products necessary for the whole of Russia. This is the principled position of our company and the management of the Group as a whole: not to make money on the situation but to make every effort to reduce the danger. Moreover, I repeat that our goal is to work directly with mask manufacturers, excluding intermediaries and speculators from the chain," the director of Polymatiz emphasised in a conversation with the journalist of Realnoe Vremya.

Although there were cases, especially at the beginning of the pandemic, when those who wanted to take advantage of the panic and “make money” on the epidemic that swept the whole world, purchased the material produced by Polymatiz and sold it, including abroad, with a tenfold margin price.

A serious difficulty in fulfilling the instructions of the leadership of the country and the republic to provide the population with personal protective equipment was caused by the lack of equipment for sewing the masks themselves on the territory of the republic at the beginning of the pandemic. Polymatiz expressed its readiness to negotiate with companies that have such lines and produce masks located outside of Tatarstan on the priority supply of personal protective equipment in short supply to Tatarstan in exchange for the material. Besides, the delivery of non-woven material in rolls to medical institutions and for home-made sewing of masks by people transferred to remote work was organised, including as a gratuitous aid.

In early April, with the support of the government of the Republic of Tatarstan, Nizhnekamskneftekhim PJSC purchased a line for the production of masks. On April 10, a Ruslan plane landed at the Kazan Airport, delivering the long-awaited equipment from China. At Polymatiz JSC (a subsidiary of Nizhnekamskneftekhim PJSC), the installation of the line began on April 11, and by 15 April, 57,000 disposable masks had been produced in the commissioning mode. All of them were handed over to those who needed them most — medical workers, law enforcement officers, employees of TAIF Group companies themselves, where the danger of the new coronavirus made its own adjustments to the organisation of continuous production processes.

“Most of the lines for the production of protective masks launched in the republic worked in one shift — that is, 8-12 hours. The management initially set us the task: to work with the maximum effect because we, as well as in the main production, were organised round-the-clock, two-shift work. We were the first in the republic to conduct a full range of technical, toxicological and clinical tests and received a registration certificate from Roszdravnadzor confirming the quality of the masks produced," Radik Yarullin, the director of Polymatiz JSC, said in a conversation with the journalist of Realnoe Vremya.

By the end of the summer, when the problem of the shortage of protective equipment — masks for the population and disposable suits for medical workers, was solved, Polymatiz JSC gradually began to produce products again for the reviving construction sector of the economy and for hygienic purposes, for example, diapers. As for medical products, last year it was more than half of the total volume of non-woven materials produced by Polymatiz. According to the director of Polymatiz, it is almost 5,370 tonnes. This includes 983 tonnes of material for making masks (about 0,5 billion pieces) and 4,383 tonnes of raw materials for making other medical products, which is enough to make almost 8,8 billion pieces of medical suits, gowns and protective suits.

To ensure the safety of personnel in the field, the entrance checkpoints of the enterprises were equipped with thermal imagers, regular sanitation of the transport that delivers workers to the enterprises, as well as working rooms, was organised. Industrial systems of active air cleansing were installed in production facilities and offices. The technology was first tested by Kazanorgsintez PJSC, and then transferred to other companies of the Group.

“In today's economic situation, the best thing is the stable operation of enterprises," said Rustam Minnikhanov during his visit to Nizhnekamskneftekhim PJSC in April 2020.

“We should appreciate TAIF as a whole and Kazanorgsintez PJSC. We saw a very high organisation of work in the conditions of the coronavirus," the president of Tatarstan said during a visit to Kazanorgsintez PJSC in May 2020.

“This is not the first time we have had a crisis, but we have always found solutions. The main thing is to preserve the existing production staff and continue to develop investment projects of TAIF Group, strategically important not only for the economy of the Republic of Tatarstan but also of the Russian Federation," Rustam Minnikhanov emphasised, who took part in the work of the board of directors of TAIF JSC in July 2020. He also assured that the leadership of the republic will make every effort and use all available opportunities to protect the interests of enterprises for the benefit of their development.

For example, in a conversation with Russian President Vladimir Putin, Rustam Minnikhanov raised the important issue such as unequal economic conditions in competition with foreign companies that produce polymers. This has become particularly relevant in the current economic situation.

“Our oil refining and petrochemistry are working, but the promotion of our products for export is difficult because our market is open, and Western partners, unfortunately, are imposing duties and restrictive measures. We are appealing to the Russian government to provide us with some support measures," he said. And he explained that Russian petrochemists are forced to pay twice — taxes at home and import customs duties in the country of export. While foreign partners not only enjoy the support of the government at home but also enter the Russian market freely — without paying an import duty of 6,5% on a number of polymers, because they are in a more favourable position. Vladimir Putin heard the request, and since September 2020 the opportunities of domestic and foreign manufacturers have been equalised.

Olefin Complex: 264 units of equipment delivered and installed

“In the conditions of increasing competition in the polymer market, it is necessary to build new and reconstruct the existing production facilities of TAIF Group. These are the new EP-600 olefin complex at Nizhnekamskneftekhim, the expansion of polymer production at Kazanorgsintez, as well as new projects for generating capacities. Besides, it is necessary to complete the Heavy Residue Conversion Complex of TAIF-NK," Tatarstan President Rustam Minnikhanov said in the message to the State Council of the Republic of Tatarstan in September 2020.

TAIF is always in motion and keeps investing its own and borrowed resources in the further development of the republic’s gas and petrochemical complex despite the global hardships for economies and the population of the whole world caused by the pandemic. Investments of TAIF Group in enterprises are measured in hundreds of billions of rubles. The construction of EP-600 complex is one of the key projects that are implemented today.

The project on the construction of an olefin complex refining 1,8 million tonnes of straight-run petrol (where besides 600,000 tonnes of ethylene, it is planned to manufacture 273,000 tonnes of propylene, nearly 250,000 tonnes of benzene, 88,000 tonnes of butadiene, 64,000 tonnes of butylene isobutylene fraction, 65,000 tonnes of C5 fraction and 17,000 tonnes of C9 fraction as well as 93,000 tonnes of tar and almost 350,000 tonnes of methane hydrogen fraction) kicked off in June 2017. A memorandum on strategic cooperation was signed between TAIF Group and Germany’s Linde AG at Saint Petersburg International Economic Forum as well as an agreement to design, deliver equipment and provide services to launch the first stage of the future complex between Nizhnekamskneftekhim and Linde Engineering. In February 2020, TAIF Group chose a contractor for construction and assembly works. Turkey’s Gemont company — a long-term business partner of TAIF that also built and assembled equipment in the Group’s another big project Heavy Residues High Conversion Complex — offered the best conditions, deadlines and a price among 29 candidates.

EP-600 with the annual capacity of over 1,8 million tonnes is the first and yet the only biggest oil refinery in Russia’s modern history. With the launch of this facility, the total amount of refined oil produced from crude oil and is a high-quality feedstock for petrochemicals will be more than 4 million tonnes a year at Nizhnekamskneftekhim PJSC. Such large facilities weren’t built even during the best years of active industrialisation in the USSR.

Works on the construction site began simultaneously with the reception of engineering documentation. Heavy equipment started to be installed in June 2020. The assembly began with a primary fractionation column that was delivered from South Korea by ship for two months. The column’s weight is 640 tonnes, the diameter is 8 metres, the height is 78 metres. After long preparations, workers began the assembly that took two days. 264 pieces of machinery, including 17 heavy units, were delivered by water during the navigation period. 112 pieces of static equipment in total were installed in 2020.

“It is a continuation of the development of our enterprise, increase of production of commodities, payments to the republican budget. This project is economically and socially profitable for the whole republic and Russia in general from all angles. The implementation of this project will allow increasing the amount of products we have been making such as rubber, polyethylene, polypropylene, and this will also enable to make new types of products we will soon learn about,” Director General of Nizhnekamskneftekhim Ayrat Safin shared with Realnoe Vremya’s journalist.

Such a significant expansion of production and scheduled familiarisation with new products will help develop not only Nizhnekamskneftekhim PJSC and TAIF Group in general but also will serve for the good of the city, the district, the republic and the country in general. The Olefin Complex is a considerable rise in taxes and payments to all budget levels (municipal, republic, federal), it creates more than 600 jobs with a decent salary, new infrastructure, including roads (highways, railways, bridges), a new impulse for housing development and the creation of social infrastructure. Moreover, it will become a driver for the appearance and development of a myriad of plants to make end products in Tatarstan and Russia in general that will use polymers manufactured in the new complex. This completely complies with the import substitution programme implemented at federal level. This is what was discussed at a meeting on the development of Russia’s oil refining and gas and petrochemical sectors in Tobolsk.

Nizhnekamskneftekhim: the market is waiting for DSSR, and we will give it the product

In 2020, Nizhnekamskneftekhim continued the construction and by the end of the year started commissioning in the sixth-generation divinyl styrene synthetic rubber plant (styrene-butadiene rubber via solution polymerisation).

“Many tyre companies have already tested our rubber and gave us the highest evaluation. The market is waiting, and we will give the market this product,” Director General of Nizhnekamskneftekhim Ayrat Safin told Realnoe Vremya’s correspondent in an interview during Tatarstan Gas and Petrochemical Forum, which was in Kazan in September 2020.

Like other rubbers made by the enterprise, this type of DSSR has valuable characteristics for tyre companies. It is used to manufacture the last layer of the tyre tread. Special features of the new product of Nizhnekamskneftekhim PJSC provide better grip, thus increasing the car’s safety. The tyres made of DSSR are frost- and wear-resistant, enable to save fuel because they have low rolling resistance, thanks to which petrol consumption reduces, the car’s environmental friendliness rises. The new type of rubber is designed to become a foundation for environmentally friendly, so-called green tyres with enhanced performance that can provide higher road safety.

The production capacity is 60,000 tonnes of DSSR a year. What is also important is that with the launch of this production, Nizhnekamskneftekhim PJSC becomes one of the few petrochemical companies in the world to arrange the production of all brands and types of synthetic rubbers that are necessary to produce high-quality synthetic tyres.

TAIF-NK JSC replaces desorber of the reactor in Petrols Plant

This year, the desorber of the reactor Р-101 was repaired in Petrols Plant of TAIF-NK JSC.

The necessity of works was noted after an examination during the major overhaul in 2017. The management of TAIF JSC decided to do a complex of works to provide safe use of units of the catalytic cracking reactor in early 2020.

A tender was announced in February 2020 where Avtotechproekt Ltd from Moscow got the right to design a complex of works to replace internal devices and substitute the lining of the desorber, including its upper conic part for a modern one-layer one. ALITER-AXI Ltd — a company from Saint Petersburg that already has a positive experience of work with TAIF-NK JSC — was entrusted with manufacturing and delivering the equipment. Perm-Globalstroyservice PLC was invited for construction and assembly works. The works were done in a short time with high quality.

HRHCC: conversion rate of light oil products is 97,5%

From the middle of May 2020, the complex’s VVC unit was provided with the design feedstock — tar. The world’s first large-capacity complex using VVC technology operates in test mode. Maksim Novikov told the Tatarstan president and people who were accompanying him about this when Rustam Minnikhanov was looking over expositions of participants in Tatarstan Gas and Petrochemical Forum.

“All measures to launch the facility are taken in our enterprise. Now we are testing it and have achieved positive results in tar refining in three months. The conversion rate of tar into light oil products is 92%. In other words, nearly all the amount of residues of oil refining (tar) is processed into light oil products,” Maksim Novikov explained to the high-ranking guests. In fact, we’re talking about a 100% conversion rate and the highest extraction of high-quality light oil products from low-margin dark residues (tar). If we convert TAIF-NK oil refinery’s feedstock, we can say that 97,5% of light oil products are made of every tonne of oil coming to the plant.”

Director General of TAIF JSC Ruslan Shigabutdinov demonstrated the products of the HRHCC or, more precisely, propane and butane fractions, straight-run petrol, diesel fuel with very low sulphur content (less than 3 ppm. To compare, Euro-5 diesel fuel’s norm is 10 ppm) as well hydrotreated vacuum gas oil and granulated sulfur to the Tatarstan president.

By the way, the exposition of TAIF Group’s companies was one of the biggest at the forum that gathered more than 100 companies of the Fuel and Energy Complex from 18 regions of Russia as well as Germany, Italy, Turkey, Sweden, Japan and Belarus in Kazan. The exposition united demo stands of TAIF-NK JSC, TGC-16 JSC, Nizhnekamskneftekhim PJSC and Kazanorgsintez PJSC. On the first day, TAIF Group’s companies already won four awards, including Nizhnekamskneftekhim PJSC got a Grand Prix in Leader of Innovations in Rubber and Rubber Goods Production and Processing.

TAIF saved Nizhnekamsk from gas hunger

The implementation of large-scale projects requires sources and higher reliability of gas supply on the territory. While there was already seen a big deficit of gas in Nizhnekamsk. And the problems with the supply of blue gas to the already operating and future facilities promised to spiral. The capabilities of the current main gas pipeline weren’t enough for the rapidly developing industrial potential of the Nizhnekamsk Industrial Hub.

Production volumes of Nizhnekamskneftekhim PJSC and TAIF-NK JSC have increased many times in the last decades, the Nizhnekamsk CHPP augmented the production of electrical energy and heat. It was made a decision to build a methanol plant, the first stage of EP-600 ethylene complex, a 495 MW power plant of Nizhnekamskneftekhim PJSC. The Heavy Residues High Conversion Complex is already refining the design feedstock in test mode — tar, vacuum gas oil, natural gas, hydrogen — and promises to run full steam soon. All these plants as well as the projects implemented by Tatneft PJSC at TANECO and Nizhnekamsk CHPP PLC together with a number of other factories and companies that have nothing to do with oil refining and gas and petrochemistry need gas. According to experts, if urgent measures aren’t taken, the unsecured demand for fuel from promising investment projects could be around 3bn cubic metres a year by 2025. This posed a threat not only to the region’s development prospects but also the operation of the already running facilities. In case of a manmade catastrophe or emergency shutdown of the existing gas pipeline, this might lead to a total failure of gas supply not only in the industrial hub but also Nizhnekamsk itself with its 250,000 people.

It was planned to solve this problem within a gas pipeline construction project Mozhga — Yelabuga — Nizhnekamsk. The management of the republic and TAIF Group held a series of talks with Gazprom. They came to an agreement, the design started and the route of the would-be gas pipeline was chosen. Conditions and terms of reference were already developed. The construction was due to end as early as 2016, however, since the administration of the country gave Gazprom PJSC very serious tasks of implementing large-scale, strategically important projects to develop main gas pipeline systems — Nord Stream 1 and 2, Blue Stream, Turkish Stream, Power of Siberia, the construction of the Mozhga — Yelabuga — Nizhnekamsk pipeline was postponed. In this situation, officials of the Republic of Tatarstan together with Gazprom PJSC made the only correct decision to build distribution gas pipelines with big throughput by and with TAIF Group’s money.

In September 2020, a solemn launching ceremony of the new high-pressure gas pipeline Gas Distribution Station No. 2 Yelabuga (Central) — Nizhnekamskneftekhim PJSC took place together with the Tatarstan president and management of TAIF Group.

The Nizhnekamsk Industrial Hub, adjacent to Naberezhnye Chelny, is one of the largest and continuing active development industrial hubs in Russia.

“The new gas pipeline, so necessary for the needs of Nizhnekamsk Industrial Hub, has been built. The dream of all petrochemists and refiners of the Republic of Tatarstan has come true. The commissioning of this gas pipeline opens up new opportunities for implementing large-scale projects in the field of petrochemistry and oil refining. It was planned to implement the project for the construction of the gas pipeline back in the Soviet Union, but only now it has become possible to implement it. The gas artery with a diameter of 1200 mm and a length of about 40 km was built in record time. I sincerely thank everyone who took part in the implementation of this unique project," Ruslan Shigabutdinov, the director general of TAIF JSC, said in his speech at the solemn ceremony of commissioning the gas pipeline. The new gas pipeline will not only allow the implementation of the projects included in TAIF Group's Development Strategy until 2030 but will also provide the necessary volumes of natural gas to the Group's plans extending up to 2050. Besides, the new gas pipeline frees up volumes to increase the volume and efficiency of gas supply to the population of Nizhnekamsk and adjacent territories, and it will also increase the supply of natural gas to Naberezhnye Chelny.

The uniqueness of the facility was that for the first time in Russia Direct Pipe technology was used for the construction of underground gas pipelines, which is a patented method for laying pipelines. This technology allowed us to reach a qualitatively new level of trenchless pipeline laying.

“This project has been implemented exceptionally successfully, and I hope very much that this experience will still be useful both in our country and in our republic. Most importantly, if TAIF Group had not made this decision, there would have been no further development of the Nizhnekamsk hub. It is huge investments. But it will all pay back," Tatarstan President Rustam Minnikhanov stressed the importance of the decision taken by the management of the Group to build the gas pipeline.

Polycarbonate Plant increased the production capacity by almost 1,5 times

Despite the pandemic and the difficult situation in general in the Russian and global polymer markets, Kazanorgsintez PJSC successfully completed the second stage of modernisation of the first and only polycarbonate plant in Russia, the CIS countries and Eastern Europe. Thanks to the upgrade, the production capacity was increased from the designed 65,000 tonnes a year to 110,000 tonnes a year.

The modernisation was carried out in two stages. The first replacement of equipment, which allowed to increase production volumes to 85-88 thousand tonnes a year, was completed by TAIF Group in 2019. A great deal of work has been done to replace the technology and modernise the production facilities for phenol, cumene, and bisphenol A. The second stage entered the active phase in the autumn of 2020.

“During the second stage of modernisation of the plant, the pumping and heat exchange equipment was replaced. The construction work was carried out only for the foundations of the new pumps," Andrey Presnyakov, the director of the Polycarbonate Plant, told Realnoe Vremya. The in-depth study of the processes and the understanding of equipment capacities by TAIF Group specialists allowed us to actually double the efficiency of the existing production facilities. At the same time, the increase in capacity did not increase the burden on the environment. Like other companies of TAIF Group, Kazanorgsintez PJSC takes maximum care of the environment.

Kazanorgsintez is preparing to increase the processing of ethane to more than 3 million tonnes a year

The need to build new capacities of Kazanorgsintez PJSC, Russia's only ethane processor, and the presence of a gas pipeline just 10 km from Kazan, which has been pumping huge volumes of so-called “fat” natural gas from the Far North to the western borders of Russia since the 1980s — these are two factors lying directly on the surface that reveal the answer to the question: why since the late 1990s the talks about the need to build a new gas processing plant near Kazan had not stopped.

The access to raw materials in Tatarstan is interesting. This has also been stated more than once. In 2016, an agreement was signed between the government of Tatarstan, Gazprom, SIBUR and TAIF on the development of a project to monetize “fat” gases. In 2019, SIBUR and Gazprom activated the work on the implementation of the signed agreement on the construction of the gas processing plant in Tatarstan, which, according to the project, was to process up to 28 billion cubic metres of natural gas a year — with the production of 2,2 million tonnes of ethane and about 1 million tonnes of LPG. These volumes are not only able to fully cover the needs of the republic for raw materials. Moreover, the programmes provide not only for expanding the production capacities of Kazanorgsintez PJSC but also involve the construction of a product pipeline to Nizhnekamsk, as well as the construction of another modern petrochemical complex near Kazan. The project is being in the research and preparation stage. Before making a final decision, the best option is selected in terms of the configuration of the future production, the technologies used and the volume of capital investments.

The territory of the area near Kazanorgsintez PJSC is attractive to build the new gas refinery and petrochemical complex for several reasons: good logistics where federal highways, railways and water routes cross, including the Sviyazhsk Multi-Modal Logistic Centre that has access to water routes.

Main oil and gas pipelines cross precisely in Tatarstan. Over 300 billion cubic metres of natural gas, more than 280m tonnes of oil and around 100 million tonnes of oil products are pumped through the republic every year. And Tatarstan in general is a traditionally developed chemical industrial region with serious industrial and workforce potential.

The operating gas pipelines pass past the potential consumer of the gas refinery’s future products — Kazanorgsintez PJSC that with its existing capacities already expresses its readiness to receive 200,000 tonnes of feedstock and more for further processing. And in case not only the gas refinery is built nearby but also capacities of Orenburg Helium Plant are expanded, where thermal energy units are already developed, Kazanorgsintez PJSC with the support of TAIF Group shareholders is ready to activate the development plan envisaging the construction of new petrochemical complexes until 2030, which will allow the company to quadruple ethane production.

The implementation of the project has a significant meaning across Russia and can have a considerable impact on strengthening the positions of Tatarstan and Russia in the global gas and petrochemical market. The launch of new production capacities will lead to the appearance of tens of new plants for further processing of feedstock across the country, which will provide the Republic of Tatarstan and Russia in general thousands of jobs, bring to a big rise in GRP and GDP, augmentation of taxes paid to all budget levels.

TGC-16 JSC: 10 years since foundation

The energy company of Group also celebrated its 10th anniversary in 2020, which was a jubilee year for the republic and TAIF JSC.

TGC-16 stepped into its second decade with serious modernisation and expansion of installed electrical energy capacity to nearly 1,670 MW and thermal energy capacity to 6,136 Gcal/h. The construction of new generating facilities and an integrated reconstruction of operating capacities enabled to take the efficiency and competitiveness of production to a new level, increase electrical (by 60% compared to 2010) and thermal energy (by 19% to 2010) by simultaneously reducing brake specific fuel consumption. This, in fact, allowed TGC-16 to save thermal energy tariffs for its wholesale and industrial consumers not above the prices of 2009 with a break-even performance.

Works on further improvement of efficiency, economy and environmental friendliness in general went on in 2020. Nowadays, after going through a selection process, the company joined a state programme designed to modernise thermal energy generating facilities and will modernise four steam turbines in the Nizhnekamsk CHPP and one in the Kazan CHPP-3 until 2026. At the same time, TGC-16 began its own large-scale programme upgrading power boilers.

In 2020, the fuel gas supply system from the Heavy Residues High Conversion Complex to the Nizhnekamsk CHPP was reconstructed by TGC-16 and TAIF-NK JSC in Nizhnekamsk. This allowed not only increasing the productivity of both plants and the efficient use of oil and gas feedstock but also significantly decreasing the discharge of inflammable gases to flare units, thus greatly reducing the environmental impact. By the way, the impact of TAIF Group’s enterprises is well below the strictest international and Russian norms.

Joint energy of Kazanorgsintez PJSC and Nizhnekamskneftekhim PJSC

The own power plants of TAIF Group’s companies will also run on syngas — a 495 MW steam turbine built at Nizhnekamskneftekhim PJSC and a 281 MW steam turbine that’s erected at Kazanorgsintez PJSC. This will give TGC-16 JSC additional opportunities to sell electrical energy in the wholesale market to both consumers of the Republic of Tatarstan and Russia in general. The idea of constructing one’s own power generating capacities in big petrochemical and chemical facilities itself is conditioned by the necessity of protecting 1st category hazardous plants from emergency shutdowns in case of manmade catastrophes, big accidents in the CHPP or electrical energy supply circuits.

“In fact, the turbines will be able to run on three types of fuel, including syngas, which is formed as waste in the production process, and hydrogen. And this direction is very promising for Siemens. So far, we have only two or three turbines in the world running on hydrogen. Small ones. In the near future, we plan to mass-produce equipment that can run on this gas. The technology of creating the special torches, capable of withstanding much higher temperatures of combustion of fuel arising from the use of syngas, has been tried is the creation of turbines for Nizhnekamskneftekhim and Kazanorgsintez,” Director General of Siemens Oil, Gas & Energy in Russia Oleg Titov told Realnoe Vremya in an interview.

“By directing synthetic gas to the gas turbine unit, the company will solve two tasks at once: supplying the CCPP with fuel and disposing of ethylene by-products,” noted President of Siemens Russia Aleksandr Liberov in a talk with Realnoe Vremya.

Works in both plants didn’t stop in the difficult 2020. So the main buildings were erected in the 495 MW Thermal Power Plant by July, their interior decoration and equipment assembly — two gas and steam turbines with generators as well as a waste heat boiler — ended, necessary networks were laid. The cooling tower 89 metres in height was almost built in September. The facility will be launched in 2021. The works are going strictly according to schedule, Nizhnekamskneftekhim PJSC stressed.

Work on the construction site of Kazanorgsintez PJSC is also underway. This facility will be put into operation in 2023.

TAIF: people as the country’s main treasure

During the global COVID-19 epidemic that was declared a pandemic, tough for the whole world, Russia and TAIF itself, Group’s companies put their main effort to fight the spread of the novel coronavirus infection and overcome its consequences as a charity event. While people had to self-isolate, and classes in schools and universities went online, enterprises of TAIF Group gifted gadgets to large and low-income families that have schoolchildren to study.

Thanks to a donation of Kazanorgsintez PJSC, Republican Clinical Hospital managed to buy 1,200 hazmat suits in early April and another 700 in July.

Nizhnekamskneftekhim PJSC has gifted 20,000 protective and 2,000 hazmat suits to health establishments since the beginning of the pandemic, the suits have been purchased due to reciprocal deliveries of non-woven fibre.

TAIF Group’s companies also repeatedly handed over personal protective equipment to health establishments, employees of law enforcement agencies and transport companies, orphanages and sports organisations. Teams of volunteers organised the delivery of food, medicines and other essentials to plants’ veterans and disabled people’s homes.

During self-isolation whose peak was in spring, including during the celebration of Victory Day, attention to veterans was especially important. All companies of TAIF Group visited veterans of the Great Patriotic War and home front veterans, gave them presents, food baskets, jubilee medals and financial aid.

Even though it was decided to postpone the celebrations dedicated to the 75th Anniversary of Victory in the Great Patriotic War because of the coronavirus epidemic and care for people’s lives and health across the country, the management of TAIF Group companies laid flowers to monuments of soldiers who died during the war on Memory Day one by one.

Nizhnekamskneftekhim’s search party had to miss a spring trip to battlefields of the Second World War because of the pandemic for the first time in 15 years. However, work went on during the forced inactivity — it just moved to rooms where archives and findings of the previous years were carefully examined. A museum of the Great Patriotic War opened its doors precisely during the tough period of the pandemic, however, online. The museum was updated with money of Nizhnekamskneftekhim PJSC. Real artefacts brought by the search party from battlefields of the Second World War are the foundation of expositions. Moreover, NKNK financed a housewarming party for the Council of War and Labour Veterans of Nizhnekamskneftekhim PJSC. A major overhaul was carried out in a new building, furniture and office equipment were purchased.

Kazanorgsintez PJSC decided not to refuse to participate in the Immortal Regiment all-Russian campaign, and the fact that doctors didn’t recommend going outside and gathering in a demonstration didn’t stop the company’s employees. The campaign switched to a safe online mode.

TAIF-NK JSC completely repaired a flat of a veteran of the Great Patriotic War by the holiday.

In Nizhnekamsk, TAIF companies organised the disinfection of streets and bus stops, developed a disinfectant, they were the only in Russia to certify a new product as medicine and set up the production of another scarce commodity during the pandemic. The development of the formula, an examination of the disinfectant and registration of the antiseptic alone cost around half a million rubles. Its own capacities of the test and production shop of Nizhnekamskneftekhim PJSC allow producing 280 tonnes of antiseptic a month. And all this happened amid an economic decline, a sudden decrease in demand, a fall in production volumes and shutdowns of tens of enterprises that consumer gas and petrochemical products around the world.

During the pandemic, from April to November 2020, companies of TAIF Group allocated over 370 million rubles to fight the coronavirus infection — and only gratis.

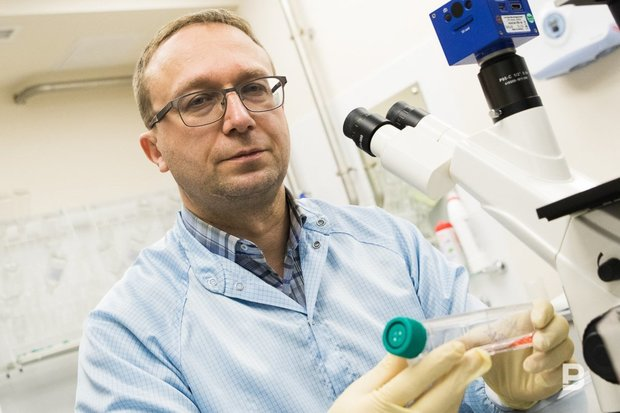

TAIF Group has always paid great attention to the support and development of the health care system. Trying to do more, on Director General of TAIF JSC Ruslan Shigabutdinov’s instruction and with shareholders’ approval, TAIF has been investing a lot of money to the country’s critical area for several years already — research and development in medicine. Group created a specialised division — DNA Research and Development Centre ANO, which initiated the creation of the Scientific and Clinical Centre for Precision and Regenerative Medicine at Kazan Federal University. It was chaired by Albert Rizvanov, professor of the Department of Genetics of the Institute of Fundamental Medicine and Biology at KFU, doctor of biological studies, PhD, correspondent member of the Academy of Sciences of the Republic of Tatarstan, an honourable professor of fundamental medicine at the University of Nottingham (Great Britain). In 2020 alone, the amount of money spent by TAIF Group on these purposes accounted for around 0,5% of the annual budget of the Republic of Tatarstan, which is hundreds of millions of rubles.

The centre equipped with modern equipment is designed to develop and use technologies of early cancer diagnostics and selection of medicines for its effective treatment and to diagnose and treat rare diseases. Together with Russia’s charity foundation Rusfond, they work on cancer diagnostics, neurorehabilitation and lymphology in children.

At the beginning of the pandemic, with the support of TAIF Group, DNA Research and Development Centre ANO and the Scientific and Clinical Centre for Precision and Regenerative Medicine are the only in Tatarstan and one of few centres in the Volga regions to join the development of a vaccine against COVID-19 and express testing systems to detect antibodies to the novel coronavirus infection in human blood. Both tasks have already become a current laboratory prototype.

At a meeting of the Tatarstan Ministry of Health, which was on 25 January 2021, the Tatarstan president, health minister and other participants in the session highly appreciated the efficiency of the testing system. Rustam Minnikhanov tasked the head of the Tatarstan Health Ministry with considering the possibility of using the testing systems to quickly do a blood test for COVID-19 antibodies within the mass vaccination against the novel coronavirus infection conducted in the republic.

By the way, the Tatarstan president is familiar with the activity of the centre, visited it and highly evaluated the training level of its employees, the quality and importance of their work. We plan to talk about this area of activity of TAIF Group and what results they have managed to achieve in a special cycle of our future reports.

During the first wave of the coronavirus outbreak when doctors working in “red zones” of special hospitals literally lived at work to reduce the risk of spreading the infection, TAIF Group came to the rescue. So The Youth camp was provided for medical staff’s leisure time and recovery all-inclusive.

When it was said that the risk was decreasing, the empty The Youth as well as other camps for children, health resorts that belong to companies of TAIF Group began operating in their usual mode, providing workers of the enterprises and their children an opportunity to have a rest, recharge their batteries and improve health.

TAIF Group companies have been a socially responsible business throughout their history. Both earlier and especially now, during the pandemic, TAIF helps health care facilities as much as it can: money is allocated for construction, major and current repairs of hospitals and polyclinics, purchase of protective equipment, prevention and treatment for workers of Group’s companies.

TAIF Group pays special attention to the health, conditions and quality of life of its companies’ workers. Apart from providing possibilities of effective diagnostics and preventive measures to improve one’s health, TAIF financed costs on the employees’ voluntary medical insurance. Needy people as well as large families and families that care about disabled people receive financial aid. A part of the mortgage is compensated, there is an opportunity to buy a new comfortable dwelling on preferential terms.

Moreover, TAIF Group actively participates in infrastructural projects, creation and maintenance of public spaces in a proper state — forest planting, cleanup of squares and parks, organisation and celebration of New Year parties, Sabantuy, Chemists’ Day and so on.

Despite the world economic decline and fall in business activity on a global scale that seriously impacted TAIF Group companies too, amateur and professional sport also receive support.

So Kazanorgsintez PJSC has been a permanent sponsor of Sintez water polo team since its foundation, as time went by, it grew into the republic and the country’s unique Sintez aquatic sports club and a real school of future champions. The club has three areas of development: water polo, diving and swimming. Athletes reciprocate the care and furiously fight for new victories. In season 2019/20, the Kazan water polo players became Russian champions. They have won this title for the second time in modern history. In August, Tatarstan President Rustam Minnikhanov honoured the winners in the Kazan Kremlin’s event hall.

Cooperation with the Russian Football Union goes on. In December 2019, TAIF JSC and the RFU signed a partnership agreement on cooperation in developing children’s football in Russian regions, firstly, in Tatarstan.

Rubin and Neftekhimik football clubs receive serious support. So Rubin’s head coach Leonid Slutsky stressed last September that he considered Tatarstan “the best sports region of the country”. First of all, because conditions for this are created here thanks to large businesses, extensively to TAIF Group. So Neftekhimik FC’s home arena — a namesake stadium in Nizhnekamsk — had a large-scale reconstruction with TAIF Group’s money, which is over 400 million rubles. It officially opened in early September 2020. Tatarstan President Rustam Minnikhanov, Director General of TAIF JSC Ruslan Shigabutdinov and the management of Nizhnekamskneftekhim PJSC participated in the ceremony.

Moreover, four indoor football pitches opened in the republic, while several children’s teams, including the Youth Sports School of Neftekhimik FC, obtained status as children’s football centre.

President of the RFU Aleksandr Dyukov expressed his gratitude to TAIF Group of Companies for the construction and support for infrastructural football facilities on the territory of the Republic of Tatarstan during his visit to Tatarstan.

“We know TAIF as a company that does a lot to develop physical culture and sport. Last year, they became a part of the RFU. Now together with them, the management of Tatarstan and UEFA, we are starting to implement a pilot project UEFA GROW aimed to develop mass football. We expect that thanks to it the number of people involved in football will significantly increase in the republic and allow preparing new talented football players for our country,” he stressed.

Ice hockey is also paid attention by TAIF Group. In answer to the care, Neftekhimik club replies with victories and serious accomplishments. So several pupils of the club successfully play around the world. Tampa Bay Lightning’s defender Mikhail Sergachyov became the first Tatarstan player in his team to win the main trophy of the National Hockey League — the Stanley Cup — last year. This happened in September 2020, while in December, with the support of Nizhnekamskneftekhim PJSC and Neftekhimik club, he visited his native town Nizhnekamsk to meet with young hockey players. While Neftekhimik team itself was in the top 10 in the updated KHL Power Rankings, which means a lot.

Even though 2020 was very tough economically: the pandemic, the saturation of the global market, a fall in demand and incomes, TAIF Group managed to not only save factories and staffs of enterprises but also continues its development. The management and shareholders of Group’s companies made a decision to reduce neither investments in Group’s Development Strategy nor the amount of money allocated to solve socially important problems as well as charity.