“The situation in the world is unclear, but our relationship is clear”: KAMAZ and Daimler open a plant worth 200 million euros

The “robotised plant” is to be loaded at 20% with Mercedes and at 80% — with KAMAZ of the 5th generation

The new production facility of KAMAZ was opened on 27 May in Naberezhnye Chelny — the cab frame plant worth 200 million euros with the planned capacity of 55,000 cabins a year. A whole brigade of VIPs with the participation of President of Tatarstan Rustam Minnikhanov, Head of Rostec Sergey Chemezov, Russian Presidential Envoy to the Volga Federal District Igor Komarov and member of the Board of Management of Daimler corporation Martin Daum arrived at the opening of the largest since the Soviet times KAMAZ enterprise. The correspondent of Realnoe Vremya found out how the new plant can help KAMAZ to overcome the crisis in the construction market, hitting the freight market with the cutting-edge freight trucks, at what pace once entirely German Mercedes-Benz is becoming Russified, and why KAMAZ and Daimler need one plant, given that the cabs of its production will be “the same” for both companies at only 20 per cent.

The plant worth 200 million euros, where the efficiency of workplaces is five times higher than of usual

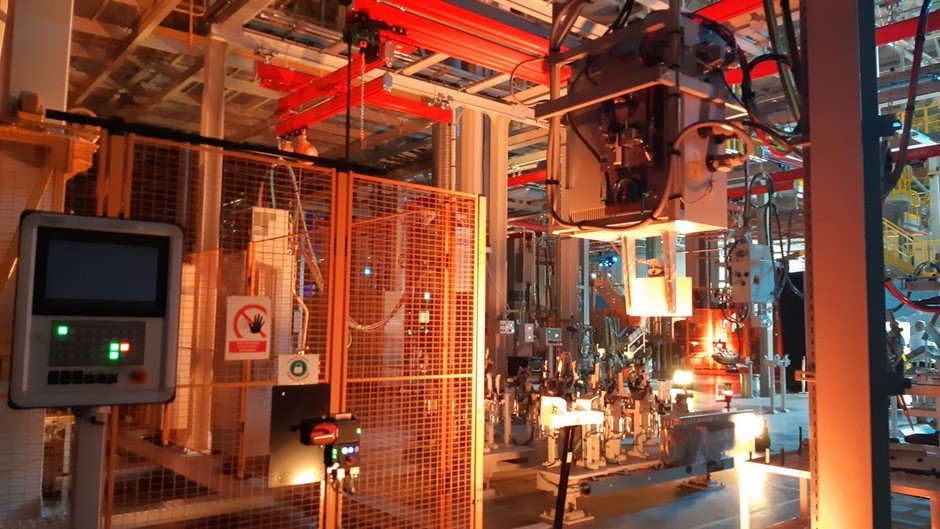

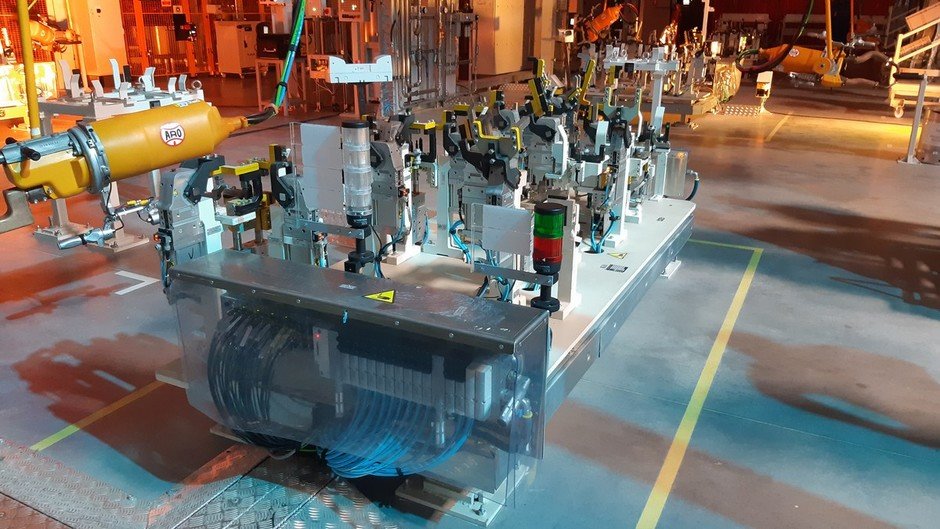

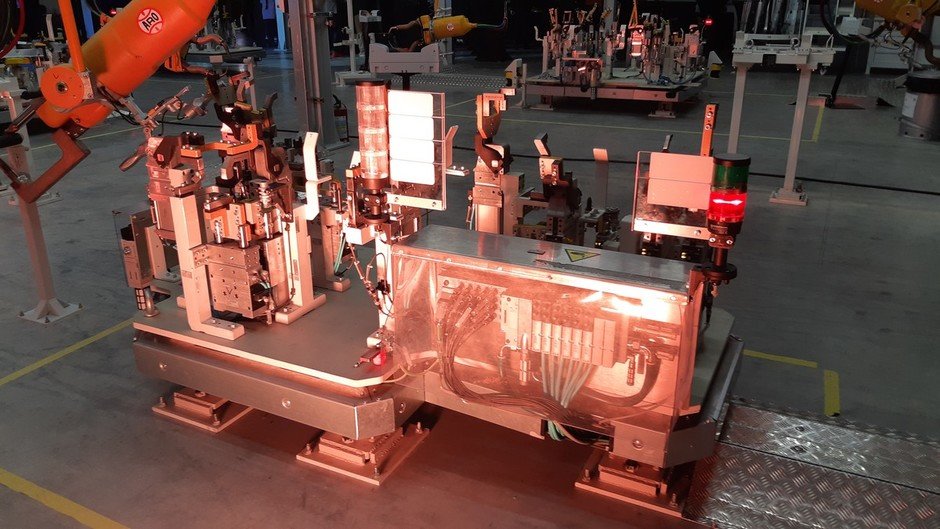

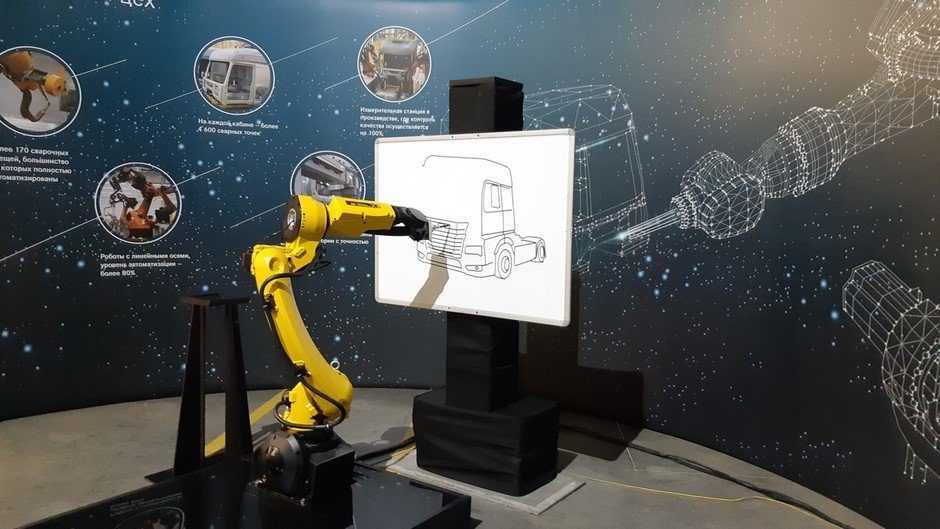

The plant represents, as they noted in KAMAZ and Daimler, a modern “digital factory” that meets the standards of Industry 4.0. Its capacity is up to 55,000 cabins a year (the planned capacity, however, is to be reached only by 2024). All processes at the enterprise, or almost all — from management decision-making to the control of technical condition of the machines and the supply of components — are automated. According to the designers, the efficiency of each workplace is five times higher than in conventional factories.

On the territory of the plant with an area of 60,000 square metres, there are located a highly automated welding shop, cabin painting shops (using “innovative technologies based on superhard paint work materials”), logistics, energy centre. In the logistics zone, where an automatic system of cabin loading into specialized trailers for their further transportation is introduced, the cabins are shipped to the assembly lines of KAMAZ and DK RUS for assembling and installation on the chassis: as the plant will assemble both cabins for Mercedes and KAMAZ of K5 generation. Many of the latest technologies have been implemented for the first time in Russia.

The total investment volume in the creation of the cab frame plant amounted to more than 14 billion rubles, or 200 million euros. However, according to Head of KAMAZ Sergey Kogogin, the investment of the auto giant itself in the plant amounted to 12 billion rubles, Daimler invested 15 billion (the discrepancy in the calculations is explained by the strengthening of the euro, Kogogin explained).

100 robots are not going to cancel human labour, the number of jobs planned is 700

As for subjective feelings, the plant really amazes with both scale and purity, as well as with the number of robotised lines (in total there are more than 100 robots). As a result, there is a feeling that the company does not need employees at all. “It is robots who work, not people”, or, as the slogans in the shops of the plant itself inform: “The future is already here”. However, despite the total automation, today the plant already employs 300 people, while it is planned that the number of jobs will eventually exceed 700.

The project is to be paid off, Kogogin admitted, only in 10 years: yes, from the point of view of business, the indicator is weak, but KAMAZ “has decided to move forward, not stand still”. According to German managers, 80% of cabins will be produced here for KAMAZ of the new generation (K5), and 20% — for Daimler trucks — Mercedes. Which is logical, as Daimler in Naberezhnye Chelny’s capacity produces about 6,000 trucks a year, which is six times less than KAMAZ produces: 80% — it is 44,000 cabins.

More than 40k new cabins will help KAMAZ to overcome the crisis in the construction market

Given the KAMAZ output level of 38 thousand vehicles in 2018 (the same forecast for 2019), they do not believe that the Russian truck market will begin to grow this year — the auto giant is now closely dependent on the development of infrastructure projects in Russia. It is thanks to them the company has been doing well in recent years: in the first quarter, usually unprofitable due to seasonal fluctuations in the market, turned out to be profitable last year. But not the first quarter of this year: the gross loss from January to March 2019 amounted to 1,12 billion rubles, net loss — 2,15 billion.

Oleg Afanasyev, the press secretary of the company, told Realnoe Vremya that it is quite a feasible task to produce 44,000 trucks for KAMAZ, it all depends on the availability of the largest infrastructure projects. The projects such as the construction of the Crimean bridge, stadiums for 2018 World Cup, allowed the auto giant to close the first quarter of last year successfully, while by the end of the year — after the infrastructure projects of the Russian Federation almost came to naught — KAMAZ had just shrunk a little. But in 2007, for example, before all crises, the company produced 56,000 trucks a year. “The Russian market today is 70,000-100,000 trucks. It is not the sales of KAMAZ have dropped, but the market itself crashed,” Afanasyev explained.

Today, the share of KAMAZ in the Russian market of trucks has approached 50% — in particular thanks to growth of sales of the freight truck KAMAZ-5490, which gave the highest increase (as the construction equipment has become less necessary but transportations have increased). As a result, KAMAZ took a market share of 30% on the freight trucks (not so long ago it did not exceed 2-3%). The new cabin will increase the market share in this segment in the future, especially since there is no pleasant news in the construction market yet.

Mercedes is becoming almost Russian

The construction of the plant itself began three years ago, and on the same year, in 2016, on the basis of Mercedes-Benz Trucks Vostok JV there was established Daimler KAMAZ Rus JV (each side invested 50% in the authorized capital). Officially, the new company is the general importer and official distributor in the Russian Federation of the Mercedes-Benz trucks and special equipment and the Fuso medium-duty trucks. Director General of Daimler KAMAZ Rus JV Andreas Deuschle is a novice, on this post he was appointed last spring. He also opened the event together with Deputy Head of Daimler KAMAZ Rus, Executive Director of the new plant for the production of cab frames Jurgen Olberding. In fact, the two parties, Russian-Tatarstan and German, took part in the press conference held 2 hours before the solemn opening of the plant. The one responsible for Russia, Tatarstan and KAMAZ was Executive Director of KAMAZ Yury Gerasimov and Deputy Director for Development of KAMAZ Irek Gumerov, for the German side — Deuschle and Olberding.

Deuschle told how a few years ago the leaders of Daimler Trucks and the leaders of KAMAZ PJSC made the decision on joint financing of the project to create the new frame cabin, although each party could invest and create the project alone. The advantages of working together, he said, in “the transfer of technology”, useful for both companies and in localization: with the help of the joint venture, the Germans will be able to increase the share of local producers in the creation of their cabins. Now the truck cabs for Mercedes-Benz sold in Russia are going to be produced also in Russia.

The role of KAMAZ will also grow: a number of parts and spares will be produced at the capacities of the Naberezhnye Chelny auto giant and supplied to the new plant. There will be no differences between the cabins produced in Naberezhnye Chelny and in Germany, the German side assured. “Our customers are used to the highest standards. Our sales directors would never accept the goods that the clients may question,” Deuschle noted. “Mercedes is beginning to Russify and becoming almost Russian!”

Jurgen Olberding said that from 2010 to 2018 the German automaker produced 30,000 Mercedes-Benz and Fuso trucks (6,000 — last year) using the capacity in Naberezhnye Chelny. He especially thanked the Russians for that the Germans finally found in Russia the manufacturer of steel that would meet the most stringent German standards. Olberding listed the details, the production of which is localized: mirrors, windshields, front frame, hinges and pedal unit, cabin beam, interior decoration, climate system.

“We had fears, but we decided to test ourselves!” sighed Olberding (not so much ourselves, we suppose, but as Russian workers).

Daimler’s and KAMAZ’s cabins will be “the same” at only 20% — the filling will be different

Gerasimov noted that the plant was built in an incredibly short time, taking into account the costs (49,000 cubic metres of concrete, 532 columns, 155,000 cubic metres of soil was excavated, etc.). At the same time, along the way, KAMAZ was building and upgrading of the press-frame plant, the engine plant (where the project was implemented in parallel with the new R-6 engine for the same KAMAZ K5), and the automobile plant. To date, KAMAZ automobile plant is ready to receive new cabins, Gerasimov says.

Irek Gumerov specified that the plant will produce not just cabins, but “series of cabins” — depending on the purpose (for freight trucks, dump trucks, etc.). In total, the plant is going to produce five basic models of the cabin, but the total number of their modifications is more than 100. The main parts for the KAMAZ cabin are produced in Russia — later Oleg Afanasyev told Realnoe Vremya that the localization of the new cabin for the K5 will reach 90-95%. The joint venture was necessary for large volumes (which directly affects, of course, the cost and profitability) and greater efficiency of the plant.

By the way, at KAMAZ we were assured that the auto giant did not “steal the cab from Daimler, as it is written in a number of media”: the share of Daimler in the new cab of KAMAZ K5 does not exceed 20%, this is the share of the frame in the entire cab. In fact, it is only the frame that unites the German and our cabin: the filling is different, since the product and directions of Daimler and KAMAZ differ.

“We are convinced that Russia has a huge potential, and Daimler will continue its cooperation with Russia”

Andreas Deuschle already at the official opening welcomed other officials not only in broken, but understandable Russian but also Tatar, what brought the workers and guests in delight: “Haerle konaklar, Rahim itegez!” Presidential Envoy to the Volga Federal District Igor Komarov did not remain aloof from the events, noting that the strategic partnership between Daimler and KAMAZ was taking place in front of him. More precisely, we could say, he watched it from the side — let us remind that in 2008-2013 Komarov headed another automotive asset of Rostec — AvtoVAZ.

“We see that Tatarstan is the region where the industry, including the automotive industry, is growing. The efforts to develop the industry give new jobs,” he flattered the authorities of Tatarstan, getting inspired by the huge “robotised shops” of the plant.

A long speech at the opening of the plant was made by Martin Daum, a member of the Board of Managements of Daimler and head of “the cargo” segment of the German Corporation, Daimler Trucks & Buses Divisions. Thanking for the support of the team of Rustam Minnikhanov, he called the plant not just “a new word in the automotive industry of Russia”, but also “the most innovative plant in the world”. He promised to continued he partnership with, describing it as “strategically important for Daimler”.

“Russia is one of the world's largest vehicle markets. Therefore, we see that we can serve this market. In 2008, we acquired a stake in KAMAZ and organized a joint venture, which has now become Daimler KAMAZ Rus, and opened a high-tech production of cabins with a very high degree of automation with more than 100 robots. In addition, if we talk about new jobs in Russia, with the new plant the number of employees of Daimler KAMAZ Rus is going to grow to 1,000 people. As for the localization of production, we also have achieved good results: for the cabin, we are already buying more than 150 components of Russian production,” Daum praised. “We are convinced that Russia has a huge potential, and Daimler will continue its cooperation with Russia.”

Kogogin compares the opening of the plant with the construction of plants for KAMAZ in the 1970s in the USSR

President of Tatarstan Rustam Minnikhanov, recalling how he several times came to the construction of the frame cabin plant, in response to the words of Daum thanked the Germans, diplomatically making it clear that it is uneasy to maintain relations with them in the cooling of relations between Russia and the West:

“I would like to thank Daimler for their decisions. It is clear that the situation in the world today is unclear, but our relations are clear! And today's project is a product of the joint work. We assure you that at the level of Tatarstan, Naberezhnye Chelny we will do everything in our power to make the project successful.”

However, Sergey Kogogin recalled that the new cab frame plant is only part of the large project for the reengineering of KAMAZ and the development of a new model range. In particular, the work is to be done to launch the serial production of the K5 truck and to attract such a number of technologies as this work required, “unprecedented for the history of KAMAZ”. Kogogin compared the new cab frame plant by the scale of construction with those enterprises that were built during the construction of the auto giant.