Anniversary year of Nizhnekamskneftekhim: record-breaking revenue, major contracts and successful import substitution programme

Nizhnekamskneftekhim's total revenue from sales amounted to 162 billion rubles in 2017, which is by 8,7 billion rubles more than in the previous year. The company has increased the production volume of synthetic rubber and plastics, which are the main products of the company. NKNK successfully continued the programme of import substitution, almost completely replacing imported analogues of linear low-density polyethylene. One of the main events of the year was the signing of the agreement with Linde AG on construction of the olefin complex. About financial and production results of the city-forming enterprise of Nizhnekamsk – read in the review of Realnoe Vremya.

Maximum output for rubbers and plastics

In the year of the 50th anniversary, Nizhnekamskneftekhim PJSC showed high production and financial results, once again confirming the status of the flagship of the petrochemical industry. Total revenue from sales amounted to 162 billion rubles. Last year, the company overfulfilled the production plan and received the maximum output of rubber and plastics. The volume of sales of synthetic rubber increased by 6%, amounting to 702,000 tonnes. 79% of this volume was shipped to large foreign and domestic consumers. The volume of sales of plastics was about 700,000 tonnes. At the same time, the net consolidated revenue of Nizhnekamskneftekhim group of companies exceeded 167 billion rubles, and gross revenue amounted to 182 billion rubles.

To increase the volume of production at the isoprene-monomer plant, the production of highly concentrated formaldehyde with a capacity of 100,000 tonnes per year was launched. This is the first of the three projects that are planned as part of the large-scale programme to increase the production of isoprene rubber to 330,000 tonnes per year. At the butyl rubber plant, the 9th line of polymerization was launched. In order to expand the range of plastics, specialists of the company mastered several brands of polystyrene for the manufacture of products contacting with food. Nizhnekamskneftekhim almost doubled the supply of linear polyethylene to Russian processors, almost completely replacing imported analogues.

New contracts with global tire giants

In the last few years, the global rubber market has shown a growth at an average rate of 2% per year. In 2017, there was a steady demand for synthetic rubbers in foreign markets, prices on average were higher than in 2016 due to a growth in the first quarter of the prices for natural rubber, crude oil and monomers.

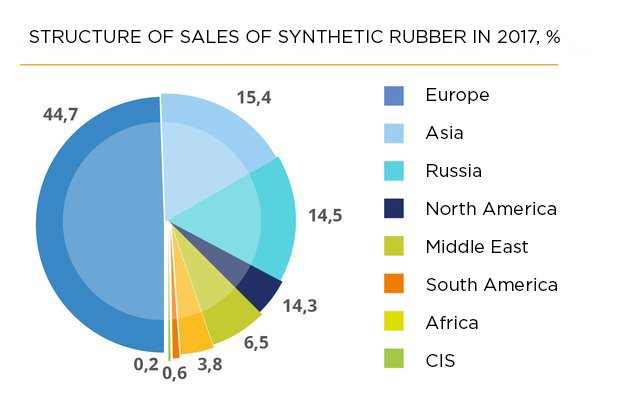

Synthetic rubbers remain the main product of the company — they accounted for 44% of sales of all products in 2017. NKNK sold 702,000 tonnes of synthetic rubber, 85% of which accounted for export markets. Nizhnekamskneftekhim is in the top 10 world's producers of synthetic rubber.

The main consumers are five world's leading tire companies with which Nizhnekamsneftekhim cooperates under long-term contracts. The parties intend to continue the cooperation, so in 2017 new contracts for the supply of rubber were signed. In June, the contract for the supply of synthetic rubbers to Michelin was signed in French Clermont-Ferrand, and in December — a contract between Nizhnekamskneftekhim PJSC and Pirelli.

In 2017, NKNK retained the status of the world leader in the production of isoprene rubber — the company accounted for 47,2% of the global market. On the world stage of butyl rubbers, the share of NKNK was 17,9%, which allowed the Nizhnekamsk company to remain the third supplier in the world. Nizhnekamskneftekhim occupies 5,7% of the world market of butadiene rubber.

In the near future, the company intends to increase the production and sales of isoprene rubber SKI-3 and commercialize the functionalized divinyl-styrene rubber produced by the method of solution polymerization.

Displacement of imported analogues on the market of plastics

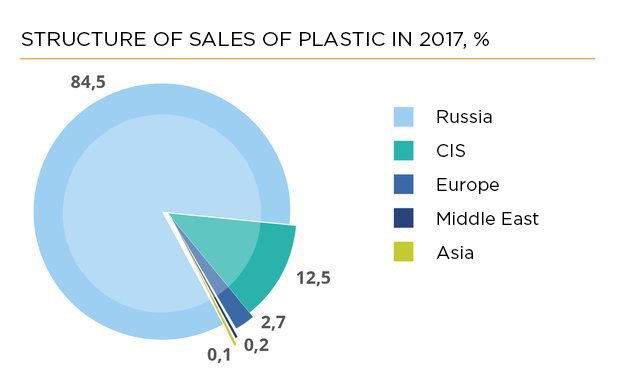

One third of the revenue in 2017 was brought to the company by plastics, which account for 33% in the sales structure of the company. The Russian market remains a priority for the company, so 85% of plastics were sold in Russia. At the same time, the dynamics of the domestic market was multidirectional. Due to a decrease in the production of high-density polyethylene, its consumption decreased by 4%. Therefore, Nizhnekamskneftekhim switched to the production of linear low-density polyethylene, the demand for which was stable and consumption increased by 8%. This was largely due to the fact that Nizhnekamskneftekhim increased its output and supplies by 70%. As a result, the import of LLDPE decreased by 43,000 tonnes. Imported analogues of linear low-density polyethylene for the production of stretch filmwere almost completely replaced from the Russian market, this niche was occupied by NKNK, as it remains the only manufacturer in the country so far.

NKNK is the leading supplier of propylene copolymers. For them, the market situation was balanced all year round, and at times there was a shortage, especially in the segment of castable and extrusion brands.

In the domestic market, the consumption of polystyrene increased by 2% in 2017. Due to good dynamics in the domestic and foreign markets, the demand for NKNK products remained high. This was also facilitated by the difference in price between imported and foreign polystyrene with a consistently high level of quality.

Nizhnekamskneftekhim once again confirmed the status of the leading supplier of polymers. Their sales increased by 5,7% compared to 2016. In the domestic market, a growth was 0,6%, in the foreign – 11,3%. In general, Nizhnekamskneftekhim took a strong place among the leaders in the production of polyolefins in 2017 and remained the largest producer of styrene plastics.

Reduction of environmental load amid production growth

Environmental protection is a priority fro the enterprise. Now the company is implementing the fourth environmental programme adopted by 2020. Since 2017 was declared the year of ecology in Russia, an agreement was signed between the ministry of natural resources and ecology of Russia, the federal service for supervision of natural resources, the government of Tatarstan and Nizhnekamskneftekhim PJSC, which provided for a number of technical and organizational measures to improve the environmental situation and educate the population on environmental issues. So, last year the company completed treatment from silt of the buffer pond of the Tungucha river, which receives runoff from industrial areas. 37,000 cubic metres of sediment were seized and neutralized. This will prevent emergency discharge of accumulated silt in the Tungucha and Avlashka rivers.

Over the year, the volume of fresh river water consumption of NKNK decreased by 1,5 million cubic metres, and the volume of wastewater — by more than 5 million cubic metres. The company reduced emissions to the atmosphere by 1,000 tonnes and waste generation — by 17,000 tonnes. By the way, reducing the environmental burden was achieved against the background of growth in the production of commercial products by 2,1%.

In 2016, Nizhnekamskneftekhim completed the first stage of the reconstruction of biological treatment facilities — the mechanical treatment unit of domestic wastewater, which improved the quality of treated wastewater. This year the second stage of reconstruction — of the node of mechanical cleaning of chemical contaminated effluents — has begun. All this will improve the quality of cleaning and eliminate odors released into the atmosphere.

Funds for charity and infrastructure of the city

To improve the housing conditions of the employees, the housing construction programme continued last year. 759 apartments were distributed: 153 apartments under the social mortgage programme and 606 apartments under the additional housing construction programme for the employees of TAIF Group. In just 3 years, over the period of the additional programme, the workers received 1,400 apartments.

Last year, the company continued to invest in the restoration of historical shrines: the island-town of Sviyazhsk and the ancient city of Bolgar. In addition, the city-forming enterprise allocated money to improve the infrastructure of Nizhnekamsk. 60 million rubles were allocated for the reconstruction of the square named after N. V. Lemaev. The architects made the square with a vertical fountain, TV pylons, play areas and large amphitheater. About 40 million rubles were allocated for the reconstruction of the territory near the ice palace Neftekhim-Arena, where pedestrian zones were made, new asphalt was laid and parking zone was expanded.

Future olefin complex and its own energy source

In June 2017, at the St. Petersburg Internationa Economic Forum, TAIF Group and Linde signed a memorandum on strategic cooperation. It implies contracts for gas separation, technical gases, but most importantly — for the four stages of the ethylene complex. The basic agreement between Nizhnekamskneftekhim and Linde AG includes the provision of technological licenses, equipment supply and technical consulting services for the new olefin complex with a capacity of 600,000 tonnes per year.

After the signing, the early stage of the project work began: the development and provision of project documentation, preparation of documents on environmental and social impact assessment, information package for preliminary investment memorandum and presentation of the project in Nizhnekamsk and local rural settlements. Important work was carried out on the organization of loan attraction. In addition, in December 2017, Nizhnekamskneftekhim signed a contract with Siemens for the construction of its own power source with a capacity of 495 MW. On the site of the old NKNK station, the German concern will build a power unit consisting of three turbines: two gas and one steam. The energy source will not only increase the energy efficiency of the enterprise, the main thing is to provide energy resources for the future olefin complex, the first of which is planned to be commissioned in 2021.

In May 2018, at the same forum in St. Petersburg, a loan agreement was signed with the syndicate of international banks with the coverage of Oiler Hermes. The creditor of this agreement will be the consortium of five German banks, mainly representing the Federal Republic of Germany, and organized by Deutsche Bank. Currently, the project documentation is being developed in accordance with the Russian rules and regulations. This summer, it is planned to start early work on preparation of the construction site.

The strategic development programme of NKNK is designed by 2023. By this time, the annual production of synthetic rubbers is to grow to 1 million tonnes, the volume of plastics is planned to increase to 1,5 million tonnes, and the production of ethylene — to 1,2 million tonnes. In the long term, the company plans to increase the volume of plastics to 2,5 million tonnes, and of ethylene production — to 1,8 million tonnes.