Kazan to start producing tests for antibodies to COVID-19 already this autumn

The test is only for evaluating the immunity

The Kazan Federal University (KFU) is launching a pilot production of test systems for antibodies to COVID-19 in the next two to three months. This was told to journalists by Albert Rizvanov, the director of the Scientific and Clinical Centre for Precision and Regenerative Medicine, Professor of the Department of Genetics at the Institute of Fundamental Medicine and Biology of the KFU, on 23 June. The development of test systems designed to detect antibodies to COVID-19 by immunochromatographic method began at the institute in parallel with the development of an anti-covid vaccine:

“To correctly evaluate the work of the vaccine, we need to assess whether there appear antibodies to the virus in the blood of experimental animals. Accordingly, this system was needed for the development of a vaccine.

But it is also necessary for practical medicine: now, according to Albert Rizvanov, this development is used in the university clinic to determine the immunity of its employees and in scientific research — to assess population immunity.

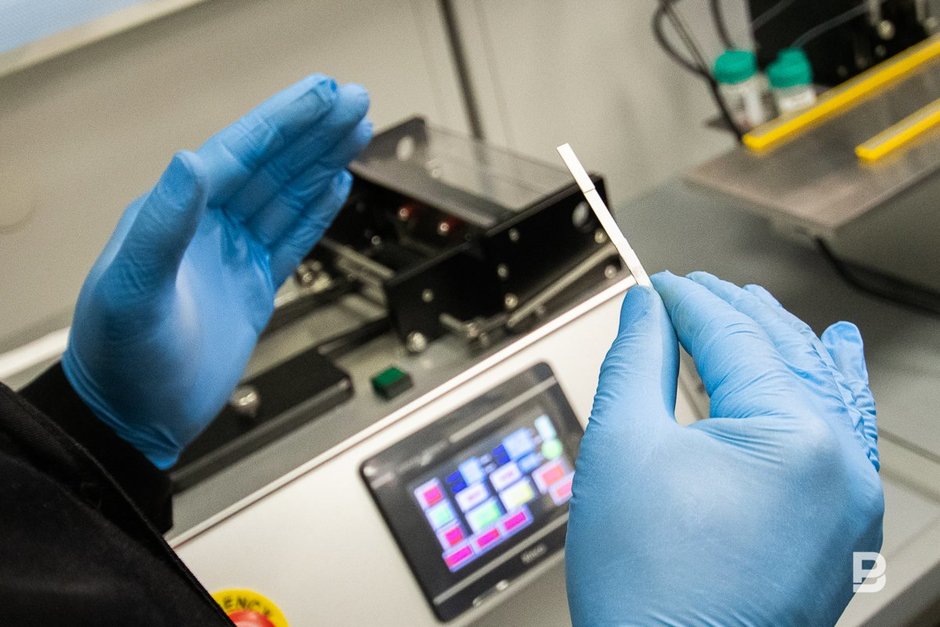

The principle of operation of the system is almost the same as that of a pregnancy test, only instead of urine, a drop of blood is applied to the test strip. The developers promise high accuracy — at least 95%. One can perform the analysis yourself by purchasing a test at a pharmacy.

But these systems, like all tests performed by the ELISA method, are not designed to diagnose the current COVID-19 disease, unlike PCR tests. They show only the presence of antibodies, and they can be contained in the blood of both a sick person and a person who has had a viral infection, but has already recovered.

Customers already there

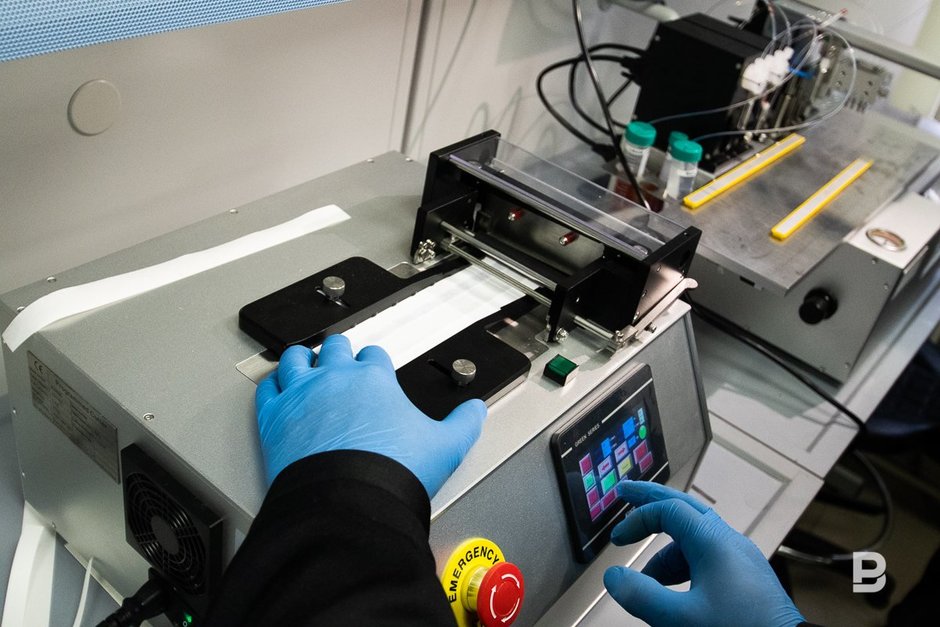

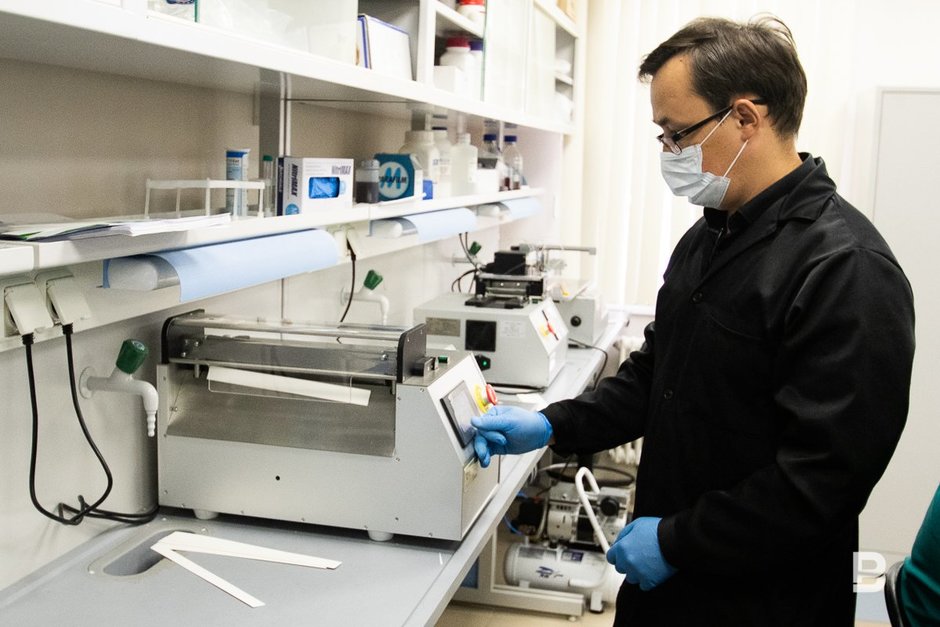

The equipment for the pilot production of tests for the detection of antibodies to COVID-19 by immunochromatographic method has already been delivered to the KFU and installed. It will take about two weeks to set up and launch — and then the KFU is planning to get the first batch of test strips. It will take about two more months to get a registration certificate:

After that, the tests can be officially used in the clinic and sold.

Albert Rizvanov added that the development of an anti-toxin vaccine based on DNA has also been completed and just today it has been administred to laboratory animals.

Answering questions from Realnoe Vremya, the director of the Scientific and Clinical Centre for Precision and Regenerative Medicine said that the capacity of production equipment is huge: more than 15,000 strips an hour, but “the practical output will be much less”. At first, the pilot release will be 10-30 thousand strips a month.

“We already have corporate clients who are ready to place pre-orders," said Albert Rizvanov. “These are large industrial enterprises that would like to test their employees for immunity to the coronavirus infection. We are also developing a project for retail packaging of test strips. And we hope that they will be available for retail sale through pharmacy chains.

Albert Rizvanov estimated the estimated cost of tests in retail sales at “from one to three thousand rubles, but not more expensive than those tests that are already available for sale — at the level of the average market”. The kit will include a test strip sealed in a plastic case, a device for piercing the finger (to get a drop of blood) and a bottle with a special liquid (to moisten the test strip and give the blood the fluidity necessary for testing).

The KFU will produce a biochemical substance for diagnostics, but the membrane — the substrate on which the biochemical component is applied for diagnostics, and the plastic packaging for tests — are imported.

The work is funded by the DNA Research Centre ANO, the cost of the project is a trade secret.

In search of population immunity

Albert Rizvanov said that employees of the гniversity clinic have already been tested. It turned out that from 20 to 30 per cent of them already have antibodies to the coronavirus. But it is not yet known whether these are antibodies to COVID-19 or to all related coronaviruses, which are quite a lot. The picture will become clearer when detailed additional research is completed.

Besides, as part of the study of the population immunity of university employees and employees of some enterprises in Tatarstan, it has been found that from 8% to 10% of the surveyed have already been ill with various coronaviruses. Rizvanov himself, in his words, is “negative for all coronaviruses”.

The “golden” tests

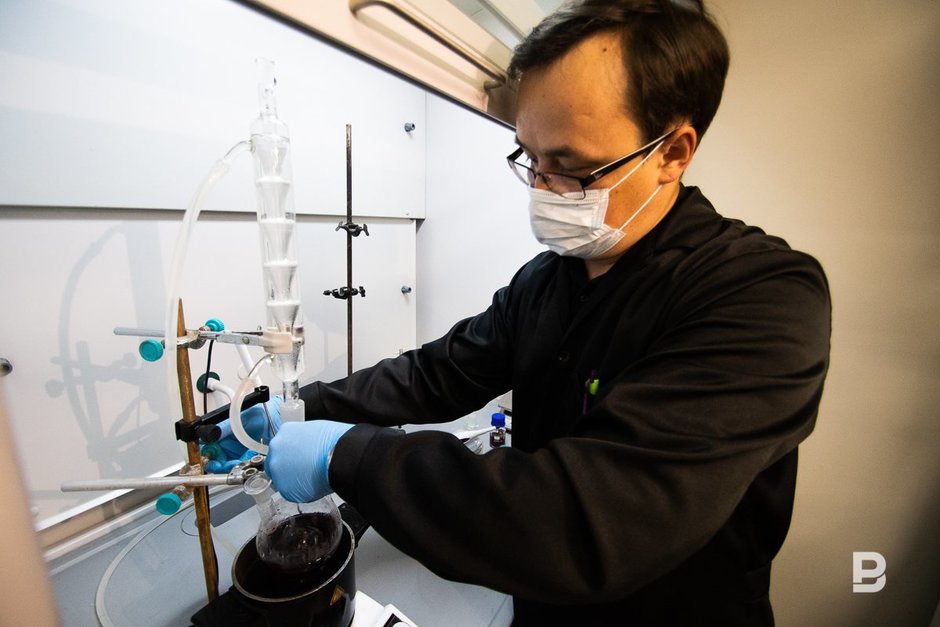

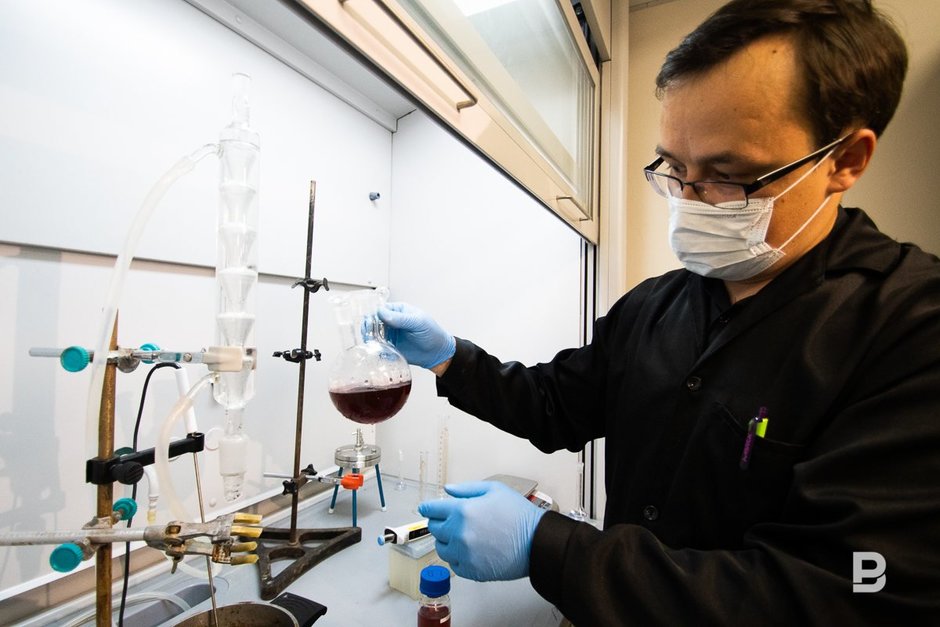

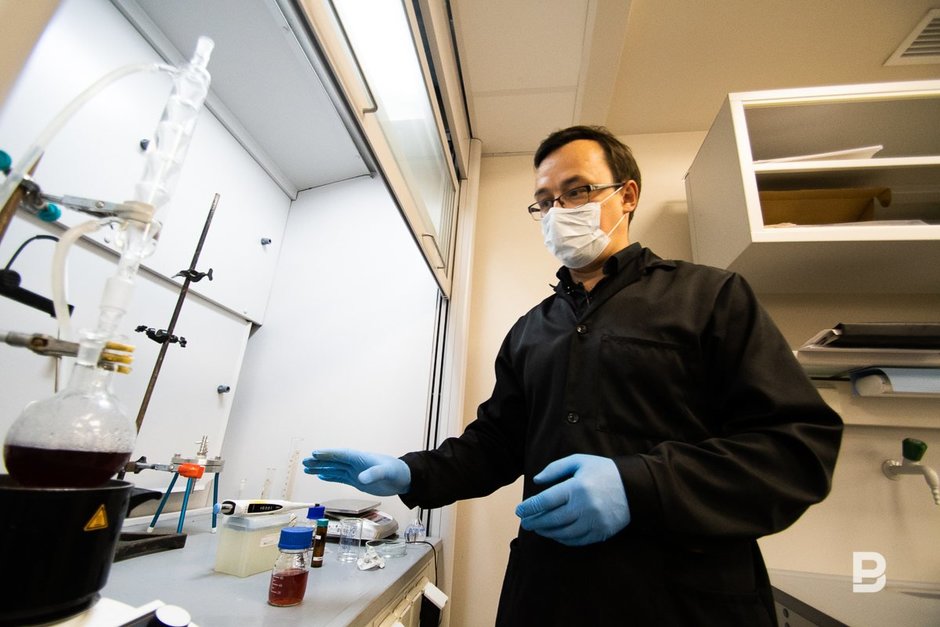

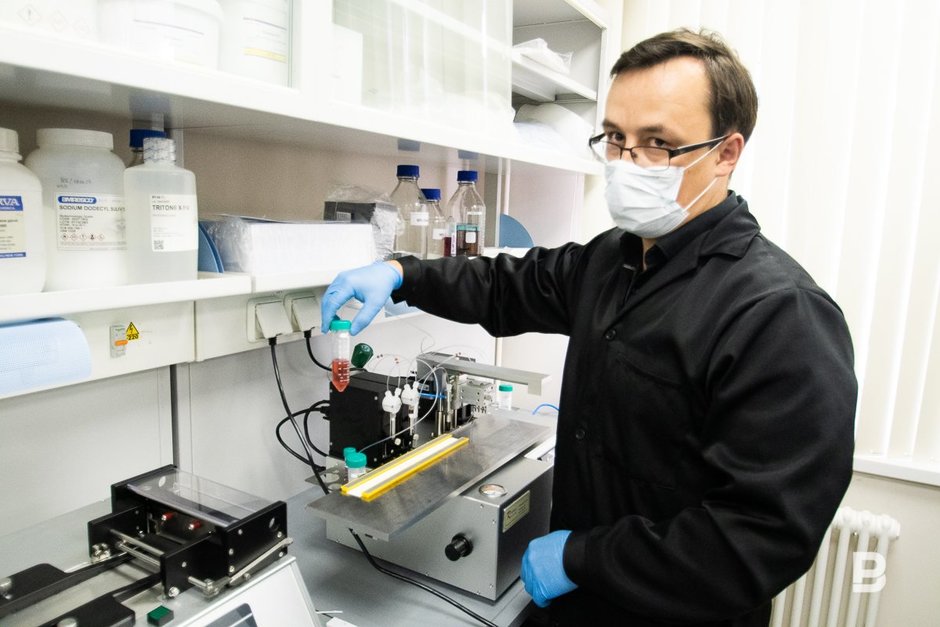

Rafil Khayrullin, a senior researcher at the Research and Clinical Centre of Precision and Regenerative Medicine, told and showed in the laboratory exactly how tests are performed at the KFU. All production is currently located in a small room — outside of it, only the production of the biochemical component is working. For the production of test strips, colloidal gold is used — the solution of dark red color. It provides staining of the membrane impregnated with a biochemical solution, and makes the antibodies “visible”.

Impregnated with the necessary reagents and dried membranes are passed through the cutter, and narrow test strips are sealed in plastic cases. Complete with the finished test, there will be a bottle with a phosphate-salt buffer — the solution of salts that brings a drop of blood to the desired area of the test strip, and a device for puncturing. The test result “appears” in 15 minutes.