''Less downtime and more production'': launch of the first smart oil wells in Russia

The first two digital twins of real oil wells at one of the fields in Perm Krai were launched in Russia on 26 March. Realnoe Vremya's correspondent witnessed the launch of the smart wells and found out what opportunities they open for oil workers. It is noted that at the moment it is the first fully operating project of this kind in Russia. However, digitalisation will soon come to Tatarstan, too.

''The project 'isn't as expensive as it might seem''

Journalists from several Russian regions arrived in Perm Krai to look at what opportunities the Industrial Internet opened for the oil sector: apart from Tatarstan, colleagues from Ufa, Orenburg, Tyumen and Yekaterinburg were interested in the smart wells. The launch ceremony with local functionaries together with heads of regional offices of Lukoil oil company and Rostelecom telecom operator was held in Lukoil-Perm PLC Central Engineering and Technological Service located in the city of Osa, 140 km far of Perm.

The CETS itself, where the smart wells were presented on 26 March, consists of four shops for oil and gas production, 16 oil fields under development as well as 1,916 million tonnes of oil.

The Aspinsky Field launched as early as 1967 became a site for the joint project of Perm oil workers and Rostelecom. Its total fund consists of 67 wells while daily production reached about 890 tonnes of oil. The work on the project began 1,5 years ago. As Director General of Lukoil-Perm Oleg Tretyakov explained, the company had been looking for a solution to collect data from the Aspinsky Field with a limited budget for long: ''We simply couldn't make additional big investments like in the north of the region, the economy didn't approve it.'' A digital twin launched together with the telecom operator became a solution to the problem.

It should be noted that a representative of Rostelecom didn't name the volume of investments citing that it was a private project. Oleg Tretyakov, in turn, also refused to answer a question about costs and said ''it wasn't free, of course''. Moreover, the director of Lukoil-Perm specified that the investments would pay back 5 years later, as the project ''isn't as expensive as it might seem'.

As for the money: speakers repeatedly stressed throughout the presentation that 90% of the Perm digital wells consisted of Russian developments. It seems that the representatives of the companies that worked on this project were sincerely surprised that our troubled import substitution was anyway working.

''The major discovery was that 90% can be made by hand here, in Russia. Even in chipset programming! Components were delivered from different regions. It's fair import substitution from iron to software. Here it's absolutely manageable prime cost, and it can be developed together with local specialists,'' Director of Rostelecom's macroregional office Ural PJSC Sergey Gusev said.

How does it work?

LoRaWAN wireless technology is the basis of the project launched on 26 March. In fact, it's radio communication operating at a frequency of 868 MHz. How it looks at the field: a data switch is installed in the mouth of the oil well whose signal goes to LoRaWAN base station, and then information is transmitted to the control centre.

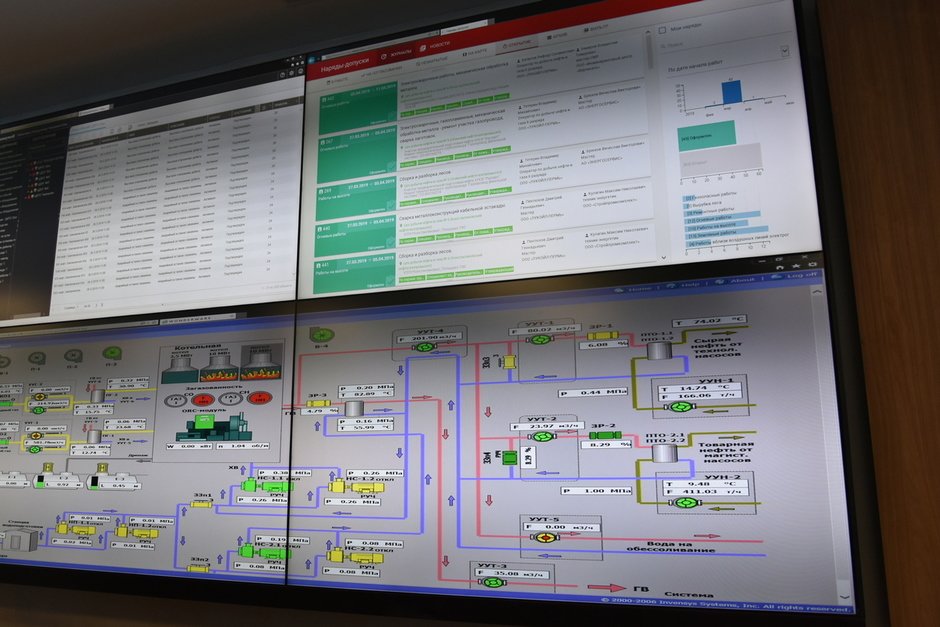

''A digital twin of the well is created in the control centre that fixes given parameters of the facility (pressure, temperature, gas pollution) and allows an operator to control the well at a distance. If more accurate measurements are needed, it's possible to increase the number of parameters of the well or the pipeline to tens, per-second data collection is also possible. Thanks to automation of processes and control over remote facilities, the managing staff can see what's going on in a facility at any moment,'' Director of Rostelecom's Ural branch Sergey Gusev explains.

At the moment, 43 in 67 wells of the Aspinsky Field, where Lukoil and Rostelecom's joint project was implemented, are equipped with measuring switches.

What's the benefit?

Generally speaking, the use of the digital twin allows oil workers to control technological equipment online and remotely control the well and change the well's performance parameters in real time mode. However, this effect of the launch of smart wells doesn't limit to it.

''If earlier it took a day for reaction, today together with the launch of this technology and the centre where specialists who see it all are sitting, the reaction process is reducing to a minimum. There was deviation in the well, specialists spent an hour discussing, gave instructions to a division on the spot. During an hour, they sit and control feedback: what happened to the well, what they did with it to get it working as usual. The downtime used to be very serious. This technology help to reduce about 28% of production losses a year,'' Director General of Lukoil-Perm Oleg Tretyakov said.

Director of Rostelecom's Ural branch Sergey Gusev confirms that the test launch, which has been carried out in the last couple of months, has already shown less downtime and more production.

Dmitry Azhgikhin told us what advantages for oil workers can be seen in using the digital twin well as well: ''We've stopped constantly bothering the staff and services and asking to go to the site. At the moment the staff has a visual view once in a shift. They used to come here 2-3 times to measure parameters, switched, launched the wells – now this is all done with the operator's remote control. We receive constant online control over the equipment's state, can control the well's performance parameters, remotely turn on and launch wells and so on.''

According to the director general of Lukoil-Perm, this project 'in its completed form is the first in Russia today: colleagues from other territories are having a pre-project preparation and discussing terms of references.'' However, as far as Realnoe Vremya is concerned, digitalisation is reach Tatarstan oil workers too very soon – the project will be implemented together with the same telecom operator.