Petrochemistry saves tens of millions of rubles due to Tatarstan scientists

Oil and gas chemistry and refinery companies' share makes up more than 58% of the volume of realization and more than 85 % of revenue of Tatarstan economy. The region is the leader in production of plastics, rubbers, the only producer of polycarbonate in Russia. In the prospects of the enterprises of that complex is to develop the product range, thus expanding the sales market and revenue in the budget. The development strategy of TAIF NK Group, which includes the largest enterprises of pertochemistry, contributes to it. The research school that operates on the basis of the universities and research centres in the Republic, of course, helps to achieve that goal. The correspondent of Realnoe Vremya found out about the role of the leading universities in Tatarstan for the petrochemistry business.

'It is not just a charity project'

September of 2015 has become long awaited for the staff and the students of the laboratory building of the Institute of Chemistry named after A. M. Butlerov, which a part of the KFU. The new building was built by the order of the President of RT with the support of TAIF and Kazanorgsintez. At the opening ceremony, the chairperson of the KFU Board of Trustees Rustam Minnikhanov recalled how he came to the Chemical Institute for the first time: the condition of the building was terrible. 'It is clear that this is a serious project. At that time, we turned to the group of companies TAIF, to Albert Shigabutdinov. And today we can thank the leadership of the group of companies for the decision taken to restore the laboratory building,' said RT President.

TAIF in the person of Kazanorgsintez CJSC has invested more than 400 million rubles in the construction of the building. 'But it's not just a charity project — we expect highly qualified specialists from there,' stressed on the opening day the head of the company Albert Shigabutdinov.

The new educational building for future chemists, the KFU students, was built in a relatively short period. Located in the historical center of Kazan, the building was designed considering stringent parameters, under the individual project to fit into the overall ensemble of adjacent buildings.

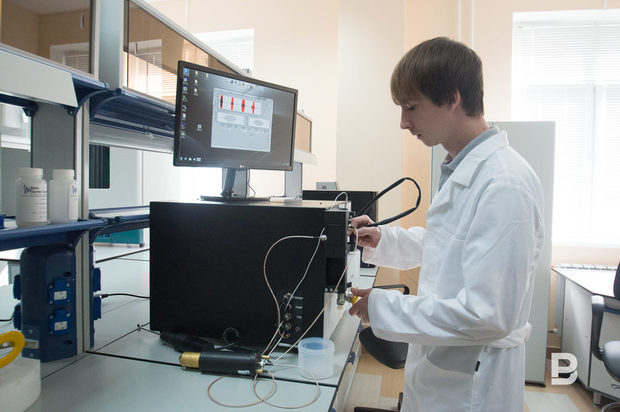

Now the infrastructure of the Institute of Chemistry named after Butlerov almost completely corresponds to the world standards of the universities. Of course, the new laboratory building has played an important role here. For already a year, 37 major laboratories equipped with modern and unique equipment have been operating in the new seven-story building. The survey works in organic chemistry, petrochemistry and in the field of fine chemical technologies and catalysis are being carried out here. All these developments of the chemists in the future will become the driving force of progress of the national companies and the whole Tatarstan.

Practical chemistry gives results

The Butlerov Institute of Chemistry is not only a source of manpower for the petrochemical industry, also the fruitful research work is being carried out here. A vivid example confirming the synergy of science and industry are the projects implemented by scientists of the KFU and Nizhnekamskneftekhim. Their fruitful cooperation in the development of new effective catalytic systems has been carried out since the early 2000s when the laboratory of adsorption and catalytic processes was created.

The beginning of the implementation of scientific developments of the industrial scale was initiated in 2012 with the opening of the high-tech production of ferric potassium catalyst required for the synthesis of isoprene in the plant of isoprene monomer of NKNK. The annual demand of the plant in this product is about 300 tonnes.

As it is known, isoprene is one of the key raw materials for the production of synthetic rubbers. Now the share of Nizhnekamskneftekhim on the global market of IR SKI-3 accounts for 43%, the volume of isoprene in the world — more than 31%. Before starting a joint venture in the operation, NKNK for many years used to purchase the catalyst for the isoprene production technology. The project cost under the contract with the Ministry of Education and Science of Russia amounted to almost 570 million rubles, out of which 250 million rubles were the state subsidies.

Two years later, in October of 2014, the catalyst factory – Catalysis-Prom OJSC — was put into operation on the territory of the plant of ethylene oxide. NKNK invested in the implementation of this joint project almost 655 million rubles of its own funds, part of which was directed to improve the industrial sites and to purchase the equipment. Another 290 million rubles — the fund of the federal budget.

The first technological line for the production of the carriers of microspheric catalyst of dehydrogenation of isoparaffins is able to produce 2 thousand tonnes of catalysts for the dehydrogenation of isobutane to isobutylene annually. This is one of the most large-scale production of catalysts for the petrochemical industry.

This catalyst is one of the most important auxiliary materials in the production technology of isoprene and synthetic rubber.

If the cost of isoprene — basic monomer for NKNK — falls, for the enterprise this will result in savings of tens of millions of rubles and, besides, will allow to increase the competitiveness of Nizhnekamsknefterkhim products on the world market.

At the completion stage — the development of catalysts for the selective hydrogenation of acetylenic hydrocarbons consisting in ethane-ethylene fraction of the ethylene plant. Its pilot tests are planned for this year. In the framework of further cooperation in 2016 it was the contract for the development of the catalyst for single-stage vacuum dehydrogenation of n-butane for the Nizhnekamsk petrochemical plant.

Besides, NKNK collaborates with the interdisciplinary centre of the KFU 'Analytical microscopy', which experts, in the framework of the contract, measure the structure of polymers, in other words, help the company to work on improving product quality to meet the international standards, which is especially topical in the framework of the import substitution program implementation.

A source of manpower for the petrochemistry of Tatarstan

It is quite obvious that the rapid development of the industry, innovation productions and technologies require highly qualified specialists and the employees of the same level. Today, the institutions belonging the KFU train such personnel able not only to conduct such complicated process but also to make own suggestions and developments to improve production.

For example, the specialized Institute of Chemistry named after Butlerov, according to the different ratings, is among the three best chemical departments of Russia along with the chemical departments of the Moscow State University and St. Petersburg State University. Besides, it has the status of one of the best science and research centers, the potential of which is commensurate with the capacity of the institutes of chemical profile of the Russian Academy of Sciences.

The Institute has nine science and research departments and seven general educational departments, employing nearly 40 Doctors of Sciences, Professors and more than 70 Candidates of Sciences. Here, we can say, the rare for the Russian industry specialists are trained. For example, in chemoinformatic and molecular modelling — this branch gives a possibility to create substances with the desired properties or to predict their structure. According to the assessments of the leadership of the University, the graduates of the Chemistry Institute have no problems with employment. They are eagerly accepted into the ranks of the employees of large petrochemical enterprises of Tatarstan, including NKNK and the KOS ethylene plant.

In spite of the fact that the KFU is a huge source of manpower, the cooperation has been established between them and the companies of TAIF Group in terms of further training of employees of enterprises. On the base of the University, the courses for advanced training for certain specialities are regularly held. In their turn, the skilled workers of companies give master classes for the students of the KFU in the framework of the 'Enterprise Factory'.

Besides, the University students do the internships on the basis of the enterprises. 'We format not only the University but also we form new training programs, which at about 40% will be adapted to the today's needs. We choose the world leaders in various fields as partners, with whom our students begin to collaborate in the second year,' said in the interview the rector of KFU Ilshat Gafurov.

Another important aspect in the training of highly qualified personnel: the Kazan (Volga region) Federal University since 1998 has been training professionals in the framework of the Federal program of professional managers training. What is more, the enterprises of Tatarstan, including Nizhnekamskneftekhim and Kazanorgsintez, participate in this program on a regular basis.

Tens of specialists of the companies of TAIF Group have been trained under the presidential program. Here, the Higher Business School of KFU under the MBA program that has worldwide recognition and high status prepare the senior and middle managers for petrochemical companies, taking into account the requirements of the system of modern management and industrial economics.

For the benefit of the Higher School

Another source of replenishment of personnel reserve for the leading petrochemical enterprises of Tatarstan is one of the leading technical universities of Russia the Kazan National Research Technical University named after A.N. Tupolev. The scientific potential of the University is almost 60 departments and industry labs, 10 science and technology centers, 3 university research institutes and the own experimental production.

The Centre of power saving technologies of RT and the head certification center for welding of the Republic of Tatarstan operate at the University. The petrochemical enterprises closely cooperate with them. One of the striking results of cooperation of Centre of energy saving technologies and NKNK is the introduction in 2014 of the international energy management certificate ISO 50001 on the basis of the enterprise in the framework of the program of energy saving and energy efficiency. The company has become the first in the country in this area.

Developed by the scientists of the Monitoring system consumption of heat and electricity center allowed Nizhnekamskneftekhim — the largest in Tatarstan consumer of energy — already in its first year of use to save more than 70 million rubles. In 2015, this result increased almost twofold due to the system of energy accounting. By the way, following NKNK the energy management systems is planned to be implemented in other enterprises that are part of TAIF Group.

Besides, the educational and methodological centre 'The Production Organization', established at KNRTU-KAI (Kazan National Research Technical University named after A.N.Tupolev) in 2010 serves as a site for training employees who in the special courses raise the level of their professional qualification.

The composition of the Board of Trustees, operating at the prestigious university of the Republic, consists of members of the government of Tatarstan – the Prime Minister of Tatartsan Ildar Khalikov, the Minister of Industry and Trade of Tatarstan Albert Karimov and the top managers of large national companies, including Director General of TAIF Albert Shigabutdinov and the head of TAIF-NK Rushan Shamgunov.

Today, the level of the KNRTU-KAI can rightfully be compared with famous foreign universities. Following their traditions, at the end of 2014 the graduates of the University decided to create an endowment fund, which is formed through donations from alumni and the partners of the University. The Fund allows to create conditions for the training and development of University students through the cooperation of the technical university with the business community on mutually beneficial terms. Today on the list of benefactors of KNRTU-KAI are nearly 70 donors.

According to the letter of the law, 'a company with the necessary licenses and professional experience' can manage the fund, This year's target capital of the KNRTU-KAI has been transferred in trust management to the TAIF-INVEST company. Today, the estimated value of the fund, taking into account the income from the management, is more than 14.5 million rubles.

It is possible to talk about the relationship of science and production for a long time. This synergy has both great achievements and still unresolved issues. But the facts are a stubborn thing: the active cooperation of the enterprises of TAIF Group with the leading universities of Tatarstan makes them truly science intensive. The results already obtained by the petrochemical and oil refining companies — Kazanorgsintez, TAIF-NK and Nizhnekamskneftekhim — are just one of the stages of a long and much needed in the highly competitive environment scientific and technological progress and the production efficiency development. So, the joint work of the scientists and the specialists of industrial enterprises continues.