Public gives the go-ahead: TAIF-NK to build a new unit

Product line of TAIF Group's oil refining company will have been replenished with another product already by the end of 2024, and the convertion rate will have approached 100%

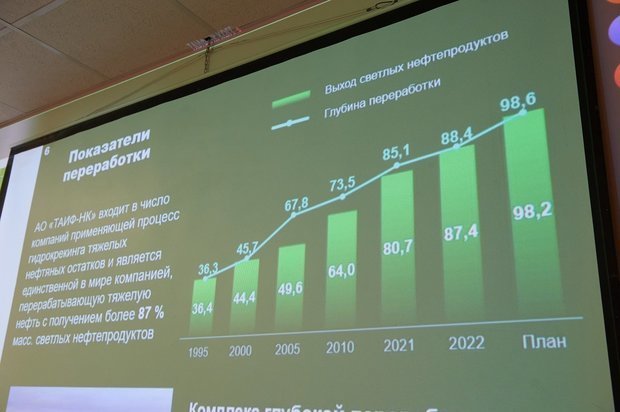

After the completion of construction and commissioning of the Heavy Oil Distillation Residue Complex, the convertion rate and, most importantly, the extraction of high-quality light oil products that do not require additional refinement at TAIF-NK have already reached record levels not only in Russia, but also on a global scale. However, the goal set by TAIF Group's oil refining company is not the current 87% of light extraction and convertion rate of almost 88,5% on average for the year, and not even 93-94%, which was achieved in some months, but as close as possible to 99% rate and 98% extraction of light ones. The new unit is designed to help make the last step towards the goal, public hearings on the project documentation of which have recently been held in Nizhnekamsk. Read the details in the material of Realnoe Vremya.

Waste or raw materials?

It depends on how you look at. For someone, mazut with tar is no more than an irritant. It would seem that the products are in demand by the market. But it's cheaper than the oil from which it is obtained. And for TAIF-NK JSC, all this is a reason to launch the processes of enhancing the convertion rate. And even with the use of technology and on a scale that had not been anywhere else in the world before TAIF Group.

How many disputes have been around the operability of the Heavy Oil Distillation Residue Convertion Complex! Today, detractors are silent, and competitors are begging to production facility: to see how everything works. The problem with the quality of crude oil and the volume of heavy residues is common for the industry.

TAIF JSC and TAIF-NK JSC are already looking further into the future: how and what useful things can be turned into from what remains after high convertion of heavy residues?

“These few percent of heavy oil products remain. Despite the small amount of these petroleum products, they are technologically, let's say, not the most useful. In the process of first distillation, and then processing at the HRCC, this residue changes its aggregate state. At the output of the unit, it is liquid, and after a few hours, during the cooling process, it turns into a mixture of a pasty substance — coke with liquid. This is a completely non-technological product: it cannot be pumped through pipes, it clogs tanks, reservoirs, and when disposed of it can produce a large amount of emissions," Aleksey Khramov, the chief engineer of TAIF-NK JSC, explained in a conversation with the journalist of Realnoe Vremya.

And it is precisely these residues of the processing of heavy oil distillation residues that will become the raw material for the new unit. But before starting its construction, it is necessary to comply with a number of mandatory requirements. One of the key ones is to get public approval.

Three weeks for discussion

The public hearings themselves took place on March 23 at the site of the Cadet Corps in Nizhnekamsk. Moreover, they simultaneously went offline, when caring citizens decided to come and personally listen to all the arguments for and against, and online — via a live broadcast in a Telegram channel with the opportunity to vote and voice their questions.

The hearings were preceded by another phase of public discussion.

“In accordance with the federal law on general principles of the organisation of local self-government in the Russian Federation, the Federal Law “On Environmental Protection”, Nizhnekamsk Municipal District and TAIF-NK JSC from March 3, 2023 began conducting public discussions on the materials of the environmental impact assessment on the object of the state environmental expertise “The unit for obtaining concentrated residue hydrocracking of tar using a mechanical high-temperature vacuum reactor”. Preliminary materials of the environmental impact assessment (EIA) of the project have been available from March 3 to the present day in electronic form on the official website of the Nizhnekamsk Municipal District, on the website of TAIF-NK JSC, as well as on the websites of Rosprirodnadzor and the Ministry of Ecology and Natural Resources of the Republic of Tatarstan. The project was placed on paper in the city of Nizhnekamsk at two addresses — in the management building of TAIF-NK JSC and in the building of the MPSC," explained Olga Chernysheva, the co-moderator of the hearings, head of the Department of Labour Protection and Environment of the Executive Committee of the Nizhnekamsk Municipal District.

The relevant notifications were published in advance on the official websites of Rosprirodnadzor, Ministry of Natural Resources of the Republic of Tatarstan, Nizhnekamsk Municipal District Executive Committee, TAIF-NK JSC.

Those who wished could leave their comments, sign up for speeches, and participate in the hearings. The announcements did not go unnoticed, as eloquently evidenced by that the total number of participants in the hearings in online and offline modes exceeded 200 people. And this is not counting the representatives of the initiator of the hearings — TAIF-NK JSC, the project organisation, the company that assessed the environmental impact of the project (EIA) and the Nizhnekamsk Municipal District Executive Committee.

With care for the environment

It was on this part of the life and activities of TAIF-NK JSC that the chief engineer of the company, Aleksey Khramov, made the main emphasis.

The production capacity for crude oil is 7,0 million tonnes a year and 1 million tonnes a year for gas condensate. More than 40 items of manufactured products. A quarter of a century of impeccable work, advanced technologies and constant striving for development — all this is TAIF-NK JSC.

And also the constant and strict fulfillment of all social obligations assumed:

“Including the full volume of the group of all tax payments and fees. From 2017 to 2022, more than 14 billion rubles were paid to the consolidated budget of our republic and more than 114 billion rubles to the budget of the Russian Federation. The company's social policy includes the development and support of working youth, patriotic education of the younger generation, the company conducts various charitable activities, participates in various republican projects. Creating safe working conditions, preserving the life and health of employees is also one of the priorities of TAIF-NC. The company operates on the principle of working ahead of the curve, which includes a whole range of preventive measures," said Aleksey Khramov.

This is one side of the social orientation of the company's work. The second, no less important, is a careful attitude to the environment and ensuring the environmental safety of production:

“All this has always been and is one of the main rules of the current and prospective activities of TAIF-NK. To ensure the environmental safety of production facilities, the Company implements environmental measures aimed at improving the environmental situation in our city. As a result of the implementation of these measures, TAIF-NK JSC managed to reduce emissions of pollutants into the atmospheric air by 33%, as well as save river water consumption by more than 11 million cubic metres, which is comparable to the volume of all water in Kaban Lake. Over the period from 2017 to 2022, more than 2 billion rubles were spent on the implementation of measures to improve the environment, which once again underlines the interest of the enterprise in reducing the negative impact on the environment," the chief engineer of TAIF-NK JSC emphasised the attention of the participants of the hearings.

Most of the gases that were previously burned at flare plants are now returned to production processes as raw materials and fuel. Emission sources are equipped with automatic monitoring systems, which increases the efficiency of control. Active work is underway to restore and increase the volume of “green lungs” of the Nizhnekamsk district. For 15 years, the company's employees have planted trees and shrubs in total on an area of more than 500 hectares. Energy-saving technologies are being actively introduced at the production facilities themselves, which also has a positive effect on the environmental situation.

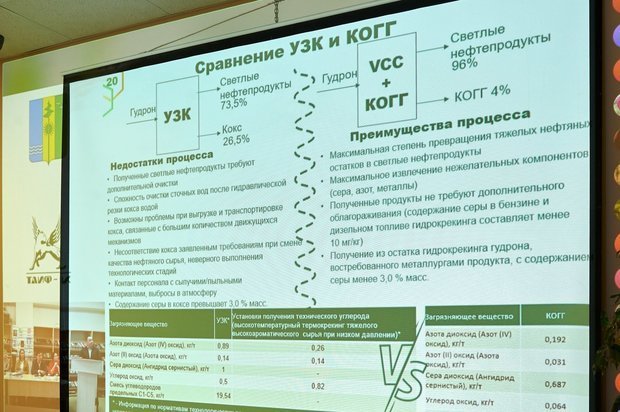

Innovations in production are also aimed at improving the ecology of the region. Production waste, which either would have to be sold as boiler fuel (far from the most environmentally friendly), or even look for ways to dispose of, get a chance to benefit by becoming popular products — vacuum gas oil and concentrated residue of hydrocracking tar (COGG), better known as pitch. And this will reduce waste from the processing of heavy oil distillation residues by more than 70% in general.

As for KOGG, it is precisely such a product that the domestic metallurgical industry has been waiting for a long time:

“Metallurgists are interested in this product as a substitute for fat, rare, scarce coals. At the same time, such pitch, in comparison with the classic coal tar or oil pitch, contains significantly less sulphur, less heavy aromatics, that is, this is another big bonus from the point of view of ecology and economics," said Aleksey Khramov. He also added: “TAIF-NK today is one of the most modern oil refineries not even in Russia, but in the world as a whole, and the logical completion of the Heavy Residue Convertion Complex is the construction of this small unit.

There are no similar units in the world

“At its core, the unit is not some out-of-the-ordinary unique technology. But! What makes it unique is its combination with the VCC complex, the scale and the conditions under which it will work. It is safe to say: you will not find a second such unit on the globe. At the same time, all technical and technological solutions have already been tested in the laboratory. Now we are talking about the scaling process," the chief engineer of TAIF-NK explained to the journalist of Realnoe Vremya.

The head of the design company, the director general of IC Technochim CJSC, Ivan Arsenyev, spoke from the podium about the completeness of the unit, its loading and the place allocated for its construction.

“The territory of the location is the Republic of Tatarstan, the city of Nizhnekamsk, on the existing production site of TAIF-NK JSC. The facility belongs to the new construction, designed for continuous processing of unconvertible residue of hydrocracking of tar with a capacity of 240 thousand tonnes of raw materials a year. Or 30 thousand kg per hour with a continuous operation time of 8,000 hours a year," he explained.

The building area is less than 1,2 hectares. The site is located on the territory of Shop No.06 of the TAIF-NK Oil Refinery. The unit will include a unit for three reactors, where, in fact, the unconvertible residue of tar hydrocracking will be concentrated under vacuum. Heating of the reactor walls will be provided by the furnace chamber. In the heat recovery unit, it is necessary to preheat the raw materials, and steam for the vacuum-creating system will also be obtained there. Next, the concentrated COG will be fed to the granulation building for grinding, and from there — to the shipment node for road and rail transport.

“The technology gives the opportunity to obtain a concentrated residue of hydrocracking of tar, which meets the requirements of the standards of the TAIF-NK organisation. Also, the technology allows to reduce the formation of waste from the existing HRCC by more than 70%. The control of the unit is from the existing operator shop No. 06 of the refinery," Ivan Arsenyev highlighted in his speech.

With a raw material capacity of 240 thousand tonnes a year, the unit will produce 112,740 tonnes of COGG and 126,640 tonnes of vacuum gas oil. The first product will be sent to companies in the metallurgical industry, the second one under the project will be poured into the raw material stream for the unit of catalytic cracking of TAIF-NK Gasoline Plant.

“The supply of the unit with energy resources will be carried out at the expense of the existing HRCC and refinery networks. The design decisions taken and the equipment used will ensure the reliability and trouble-free operation, as well as the safety of operation. At the same time, according to the handbook of the best available technologies, emissions of pollutants into the atmosphere from classical delayed coking plants in almost all parameters exceed similar indicators from carbon black production plants, that is, the technology that is comparable to the COGG unit. That is, this unit is much more environmentally friendly than the DCU," Ivan Arsenyev stressed at the end of his speech.

Environmental load will increase slightly

This is the general meaning of the speech by Galina Kuznetsova, the deputy head of the ecology department of STC Pozhengineering PLC, on the results of the environmental impact assessment of the project (EIA).

According to the expert, the main tasks of the EIA in the preparation of preliminary materials are:

- assessment of the current state of environmental components and the identification of environmental restrictions in the area of the projected facility;

- elaboration of alternative options for the implementation of the planned activity, including the zero option — that is, the rejection of the planned activity;

- impact assessment during the construction and operation of the facility;

- development of a set of environmental measures to minimise the negative impact of the projected object during its construction and operation;

- conclusions on the degree of residual impact taking into account environmental measures;

- calculations of environmental payments and compensation payments;

- ensuring public participation in the preparation and discussion of EIA materials.

According to the results of the EIA, the unit, which will be built on the territory of the existing production of the Nizhnekamsk industrial complex, has more than sufficient distance from rivers, lakes, specially protected natural areas and objects of cultural and historical significance, which means that the emissions of future production do not pose the slightest threat to them.

“There are no water intakes, surface and underground sources of economic and drinking water and water supply within the boundaries of the site of the projected object. There are also no sources of drinking and household water supply in the sanitary protection zone. There are no deposits of common minerals and underground waters on the territory of the projected facility. The site of the projected facility is located outside the borders of anthrax cattle burial grounds, biothermal pits, and their sanitary protection zones," Galina Kuznetsova continued to list the absence of restrictions for the construction of production facility.

The most exciting issue for residents of Nizhnekamsk is the impact on their lives of the appearance of another oil processing plant. Kuznetsova's answer: it will not affect in any way.

“The total emissions of TAIF-NK JSC will increase slightly after the project implementation. Only 1,9% of the permitted maximum permissible emission. The level of atmospheric air pollution by emissions from the facility being created on the border of the unified sanitary protection zone of the Nizhnekamsk industrial complex and in the residential area will not reach 0,1 MPC. The level of emissions generated by the productions of TAIF-NK JSC and the projected unit, taking into account the background at the border of the sanitary protection zone of the enterprise, does not reach 1 MPC. That is, according to the results of the performed dispersion calculations, taking into account the background, the maximum concentration of all pollutants will comply with the established sanitary and hygienic standards in the residential area, on the border of the unified sanitary protection zone of the Nizhnekamsk industrial complex and in the sanitary protection zone of TAIF-NK JSC both during construction and during operation of the projected unit," she summarised.

Taking into account the extent to which TAIF-NC's efforts have already made it possible to reduce the amount of environmental impact (already significantly falling short of the upper limit of the MPC), the results of the EIA only officially confirmed what is already known.

Questions and answers

After the completion of the main part of the hearings, the participants had the opportunity to ask the most exciting questions and get answers to them.

Rinat Kurmanov was interested in whether new jobs would appear after the unit was put into operation. The answer: yes. The company will need another 30 specialists to work at the new production facility.

Nikolay Tukeev was worried about how much the company needed this unit at all and what benefits TAIF-NK planned to get from its construction. The representative of the designer, Ivan Arsenyev, answered on behalf of the company:

“First of all, the benefit is getting rid of waste from the processing of heavy oil distillation residues. About 70% of all waste will be recycled. There is also an increase in the marginality of TAIF-NK JSC due to that the product obtained by KOGG will be sold to metallurgical companies, and vacuum gas oil will become the raw material for the Gasoline Plant.

The deputy head of the Nizhnekamsk Municipal District executive committee, Rafael Igtisamov, also had a question. As the representative of local authorities, advocating for the development of the municipal district, he was concerned about the amount of investments and project implementation period.

“According to the company's calculations, investments in the implementation of the project amount to 4-4,5 billion rubles. The terms of implementation, taking into account the receipt of the project working documentation, are estimated at 1,5 years," Aleksey Khramov answered both parts of the question at once.

Supported unanimously

The final of the public hearings was the vote. Those who were present in the hall did it by the classical method — raising their hands. Those who took part in the hearings remotely received a minute to answer each of the two questions.

The first one sounded like this: “To recognise the public hearings on the object of the state environmental expertise as having taken place: 'Project documentation for the facility 'The unit for the production of concentrated tar hydrocracking residue using a mechanical, high-temperature vacuum reactor', including preliminary EIA materials.” The result after counting all the votes: for — 207, against — 0, abstained — 2.

The second question: “Planned events for the planned activity — the implementation of the project to obtain concentrated residue of hydrocracking of tar using a mechanical, high-temperature vacuum reactor — have been approved and supported by the participants of the hearings.” There were neither abstainers nor those who were against it at all. Unanimous in favour.

TAIF-NK JSC has received public approval and can now begin the active phase of the project implementation. According to preliminary calculations, in a year and a half, that is, by the end of 2024, construction works are to be completed, the equipment are to be put into commissioning, and the new production is to be put into operation.