Taif Lubricants: becoming leader in premium segment of synthetic oils in Russia

TAIF-SM PLC, the first and only manufacturer of polyalphaolefin lubricants in Russia, is focused on replacing imported high-performance oils and lubricants on the Russian market. The improved technical and technological base of the Synthetic Oils Plant (Taif Lubricants brand), as well as its own research platform, made it possible to create an innovative production in Nizhnekamsk, whose products are not inferior, and in some ways surpasses foreign analogues. About the ever-growing demand of the market, product range developments, and ambitious plans for modernised production — in the material of Realnoe Vremya.

Revival of the plant through complete modernisation

The production complex for the production of lubricants was built and put into operation in Nizhnekamsk in 2003. At the initial stage, the company was a joint project of Nizhnekamskneftekhim PJSC and Tatneft PJSC and was named Tatneft-Nizhnekamskneftekhim-Oil. However, the plant, which had reached its design capacity by the end of May 2004, was stopped literally a year later — in December 2005. The reason was, among other things, as Kommersant wrote back in June 2005 with reference to the management of the enterprise at that time, “serious design and technological errors” made by the licensee and the designer, as well as low demand for the company's products. In December 2008, arbitration management was introduced at the plant, and in October 2012, the company was declared bankrupt with the introduction of bankruptcy proceedings. In 2014, when Tatneft-Nizhnekamskneftekhim-Oil was put up for auction twice, it failed to find a new owner. The Synthetic Oil Plant got a chance to revive in January 2019, when it was bought out at open auction. In the same year 2019, TAIF-SM PLC was created, which became part of TAIF JSC.

Immediately after the change of ownership in production, with the support of TAIF JSC, large-scale modernisation began, aimed at correcting errors and shortcomings made at the construction stage of the plant, and turning into a modern, world-class complex that fully meets the requirements of industrial safety and Russian legislation. The purpose of modernisation is to ensure the industrial production of high-quality commercial lubricants that were not previously produced in Russia. At the same time, there was a rebranding: the products that the Synthetic Oils Plant was to produce would conquer the Russian and foreign markets under the name Taif Lubricants.

“Modernisation has affected almost the entire plant: new technological lines, filtration, automation and control systems have been installed in the workshops for mixing commercial oils, polyalkylene glycol base oils (PAG) and in the PAO lubricants synthesis workshops. There appeared a technological chamber for the preparation and heating of additives, lines for packing oil into containers of different volumes. The loading/unloading racks and consumption tanks have been completely updated. The specialists worked on the settings of the equipment for the production of PAO lubricants, designed by the Serbian company NIS-Engineering, and achieved the production of consistently high-quality product. With the help of TAIF JSC, a team was formed and in the shortest possible time the production facility was put into operation and brought to technological design indicators," said Ruzil Vafin, the director of the Synthetic Oils Plant.

The area of the factory territory in Nizhnekamsk is 3,9 hectares, of which the production facilities occupy 2,7 hectares. The company employs more than 250 specialists.

During the modernisation, special attention was paid to ensuring the necessary industrial safety, inconsistencies were reconciled, and a license for the operation of the Synthetic Oils Plant of TAIF-SM PLC was obtained. New equipment from leading world and Russian brands was installed for processing linear alpha-olefins to obtain polyalphaolefin base oils from them and to create high-tech commercial oils based on them. The new production and filtration system ensures the purity of the final product with a class of at least 6-8 units in a container (according to GOST). In other words, the products are almost completely free of any mechanical impurities larger than a bacterium, which significantly increases the life of filters installed on machinery and equipment of end users of products.

A modern reliable system of automatic feed of raw materials has been installed in the mixing workshops, ensuring high accuracy of dosing of the supplied components.

During the modernisation of the packing unit for commercial oils, consumable tanks were installed, allowing for the simultaneous packing of up to four different types of oil. Three automated lines are capable of packing products into containers of almost any capacity with high accuracy — from a barrel to a canister. For the shipment of goods in bulk, the unit of the loading/unloading rack has been completely re-equipped. Only the frame remained of the old node, and the equipment was replaced with a new one. Two filling units for flammable liquids (oils) and one filling unit for flammable liquids are equipped with ultra-precise mass flow meters. All the work was carried out in record time for the restart of such a large-scale and complex production. Already in December 2020, the first, experimental batch of products was shipped. To date, modernisation does not stop, design and survey works are underway to increase the capacity of the workshop, and a modern line for packing oils into small containers of domestic production of Mekhatronika MVS has been purchased.

State-of-the-art laboratory equipment from leading manufacturers of the industry provides continuous six-stage quality control of lubricants manufactured in accordance with Russian and international standards. Only those formulations that are guaranteed to meet modern high requirements are put into mass production and sale.

The commercial oil shop includes seven reactors with a total volume of 92 cubic metres. Currently, the Lubricants Plant is ready to produce 15,000 tonnes of commercial oils of a wide range and 9,000 tonnes of PAO lubricants a year.

“The company is currently operating at its design capacity. The volume of increase in productivity and timing depend on the pace at which we will increase the volume of sales of our products on the market," said Vitaly Baron, the deputy director general of TAIF-SM PLC for production. The capabilities of the installed equipment give the opportunity to increase production volumes to 60 thousand tonnes of lubricants and more than 10 thousand tonnes of PAO lubricants a year.

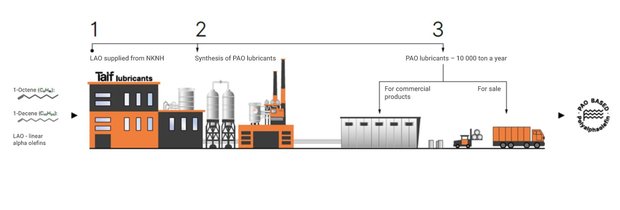

The production of lubricants manufactured under the Taif Lubricants brand is a complete technological cycle from the reception of raw materials from Nizhnekamskneftekhim PJSC to the development of its own formulations and the production of ready-made commercial lubricants and base oils of Group IV (PAO lubricants) according to API in industrial volumes, their packaging and shipment to distributors and consumers.

The range of products manufactured under the Taif Lubricants brand is more than 270 items presented in all segments of ready-made commercial oils in Russia:

- motor and transmission oils for passenger vehicles;

- engine and transmission oils for commercial, cargo transport and special equipment;

- industrial oils for various industries;

- oils for the food and pharmaceutical industry;

- water-miscible and oil-based lubricants and coolants for metalworking;

- oils based on polyalkylene glycols and esters;

- lubricants and pastes based on polytetrafluoroethylene and silicones.

The plant already produces lubricants (motor and industrial oils), basic synthetic oils (PAO-2 — PAO-10). In 2021, a new line of PAO for 1-octen raw materials was introduced, as well as commercial batches of medium-viscosity and high-viscosity PAO (PAO-20, PAO-40, PAO-100, and PAO-1000) were produced, in the future it is planned to produce antifreeze and plastic lubricants.

Russia is one of the world's largest manufacturers of lubricants

To understand the role of the plant in the economy, it is important to understand the volumes and dynamics of this market. If we talk about the volume of lubricants consumption, then Russia is one of the largest markets in the world, second only to the USA, China, and India. The modern lubricants market (both Russian and world) can be conditionally divided into two parts: the market of base oils (the basis for the production of lubricants), as well as the market of ready-made commercial oils and plastic lubricants.

“The total volume of the Russian market for the consumption of finished commercial lubricants in the Russian Federation by the end of 2021 was estimated at 1,718 thousand tonnes. Approximately 24% of the domestic lubricants market is accounted for by passenger vehicles. For the production of base oils, the Russian market is in surplus, and some of the base oils produced in Russia are exported," Dmitry Bugaev, the director for commercial affairs at TAIF-SM PLC, said in an interview with Realnoe Vremya and explained:

“According to the classification of the American Petroleum Institute (API), base oils are divided into five categories:

- Group I — base oils obtained by selective purification and dewaxing with solvents (conventional mineral);

- Group II — highly refined base oils with a low content of aromatic compounds and paraffins, with increased oxidative stability (hydrotreated oils — improved mineral);

- Group III — base oils obtained by catalytic hydrocracking (HC-technology). They have a high viscosity index, have undergone special treatment, and are close to group IV synthetic base oils (semi-synthetic base oils) in molecular structure and properties;

- Group IV — synthetic base oils based on polyalphaolefins (PAO). Synthesised from ethylene, they have an equal molecular structure, complete absence of impurities, very high oxidative stability and a high viscosity index (synthetic oils);

- Group V — other synthetic base oils not included in the previous groups, including silicone, phosphate ether, polyalkylene glycol, polyesters, bio-lubricants, etc. used in combination with other base oil to improve the properties of the final product.

Russian government agencies, in turn, divide basic and commercial oils into “mineral oil” and “synthetic oils”. Only TAIF-SM produces synthetic base oils based on PAO.

“The cost of group I base oils, like any other exchange-traded product, is determined by the market, not the manufacturer itself. Group II base oils were not produced on the Russian market until 2022. In 2022, Rosneft changed the technology to YANOS (Yaroslavl Refinery) and began producing Group II instead of III. Group III is produced by TANECO and LUKOIL, while the latter prefers to use the product for the needs of its own production or to sell it for export.

There is only one producer of group IV base oils, polyalphaolefin, in Russia — the synthetic oil plant in Nizhnekamsk.

Designed for aviation, but proved to be in demand everywhere

PAO or polyalphaolefin base oils are produced by synthesis from linear alpha-olefins, which, in turn, are obtained from gas (ethylene). PAO-based motor oils can be classified as “classic” synthetic lubricants.

An interesting fact is that initially PAO-based lubricants were created for aviation, where the operation of equipment occurs at significant temperature differences — from high plus to serious negative values. This required a special approach to the choice of lubricants, and PAO with a solidification threshold of up to -60 ° C and the ability to maintain working viscosity at high temperatures turned out to be the best choice. Besides, PAO retain chemical stability during operation, do not have impurities (sulphur, resins, high-setting paraffins, inorganic components), practically do not evaporate and have high viscosity at high temperatures.

Today, polyalphaolefin oils are actively in demand for passenger cars, including racing equipment, for heavy-duty vehicles operating under constant load and in the conditions of the Far North. PAO lubricants have proven themselves well in production, ensuring reliable operation of various industrial equipment. The scope of use of PAO lubricants is actively expanding. Polyalphaolefin base oils are an environmentally friendly product, do not contain carcinogenic substances, sulphur or chlorine. In other words, the choice of PAO lubricants is a significant contribution to the care of the environment.

The Russian market, as well as the European one, especially in the current geopolitical situation, is experiencing a shortage of Group IV base oils. This is primarily due to the limited production capacity of European sites. The only available channel for the purchase of polyalphaolefin lubricants in Russia until recently was exclusively import. But with the launch of the updated plant, which has undergone a deep modernisation, the Russian market will be supplied with Russian-made PAO lubricants, similar in quality to imported synthetic oils.

Polyalphaolefin oils are produced from raw materials supplied by Nizhnekamskneftekhim PJSC. Strict quality control is carried out at all stages of production — from acceptance of purchased raw materials to shipment of finished products to the consumer. After the modernisation of the Synthetic Oils Plant in Nizhnekamsk, all the main and auxiliary stages of the production of 1-decene oligomers intended for the production of polyalphaolefin bases of synthetic oils were brought to a well-established technological level of work. The production of a wide range of premium-level lubricants can be arranged on the basis of the PAO lubricants of the Plant of Synthetic Oils.

The main physical and chemical parameters of PAO lubricants of Taif Lubricants correspond to foreign analogues used in the production of lubricants, and meet (and in some characteristics exceed) current requirements of international OEM producers.

Business cannot develop in isolation from science

The synthetic oil plant is an innovative enterprise. Not only from the point of view of the availability of PAO lubricant production equipment unique for Russia, but also in the fact that, simultaneously with the modernisation of the production component, much attention was paid to the recruitment of personnel to the established own Research and Development Center (R&D). The center is headed by Sergey Agabekov, the deputy director general of TAIF-SM PLC for science.

The purpose of the Center was the development and adjustment of formulations of commercial lubricants and the rapid creation of new products according to customer requests. It is worth noting that the vast majority of products produced by the plant are the own development of the Research and Development Centre (R&D). The development was carried out in cooperation with recognised global additive suppliers such as Afton, Lubrizol, Infineum and BASF. In today's macroeconomic and geopolitical environment, rapidly changing market conditions, TAIF-SM PLC has reoriented additive procurement channels to the markets of Asia and the Middle East. The Research and Development Center promptly adapted oil formulations taking into account the correction of the raw materials portfolio of additives, providing production conditions for supplying consumers with premium quality products.

The laboratory for monitoring the condition of lubricants successfully operates on the basis of R&D. Laboratory analysis of oil, greases and hydraulic fluids gives a quick and accurate picture of what is happening inside engines, gearboxes, compressors, hydraulic systems and other critical mechanisms. Effective monitoring makes it possible to optimally plan maintenance, reduce the risk of damage to expensive installations and avoid unplanned downtime. Any company can apply for a qualified analysis of lubricants of its own capacities and get an assessment of the results indicating the risks and recommendations for their exclusion.

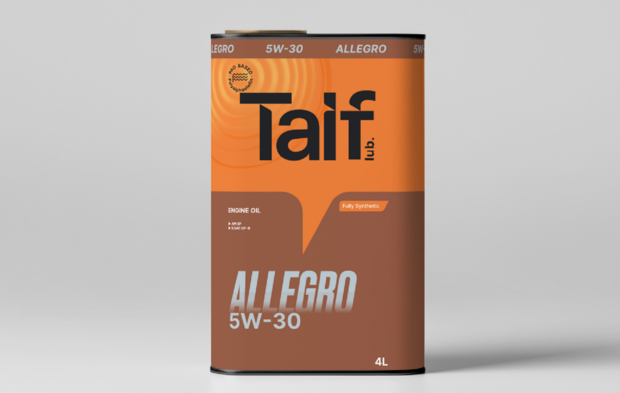

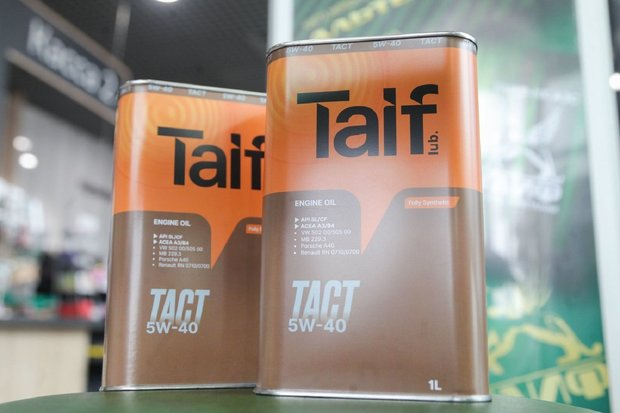

“The availability of our own basic components and cooperation with advanced European and Asian additive manufacturing companies provide a competitive advantage over foreign manufacturers and allow us to produce flagship gear, turbine, compressor and other oils, such as TAIF MODUS PAO, TAIF RAVE PAO, TAIF HARMONY PAO. Outside of the industrial sector, PAO lubricant-based engine oils for commercial and passenger vehicles are manufactured at the enterprise that meet the requirements of domestic and international standards, including the largest car manufacturers such as Mercedes-Benz (Daimler), Volkswagen, Porsche, General Motors, etc. It is worth noting that against the background of the geopolitical situation, the latter are now massively withdrawing the approvals previously issued to Russian manufacturers of motor oils. The functional characteristics of such oils as TAIF ALLEGRO and TAIF VIVACE guarantee high product efficiency when used in harsh climatic conditions in Russia. In March 2022, we launched a line of lubricants and coolants that are critically important for the metalworking industry sector of the Russian Federation. The line consists of water-miscible liquids — TAIF C-Fluid and oil — TAIF-C-Cut," Sergey Agabekov emphasised. In September 2022, the first batch of oil for hypercompressors in Russia was produced entirely on domestic raw materials. The hypercompressor is the heart of any enterprise producing polyethylene. This development was carried out jointly with SIBUR and the Gubkin Russian State University of Oil and Gas.

The divisions involved in the development of the company's products work closely with all the main centers of competence in the field of lubricants, such as Gubkin Russian State University of Oil and Gas (we have many graduates of the specialised department of lubricants, and also in July 2022 there was an internship for 25 students of this university), the 25th State Research Institute of Chemmotology of the Ministry of Defense of the Russian Federation, the All-Russian Scientific Research Institute for Oil Refining in terms of research and the latest developments, operational tests and obtaining approvals for the use of manufactured lubricants in specific conditions," the deputy director general for science also noted.

The centre does very complicated tasks of picking formulas of lubricants that meet requirements of both operational conditions of separate parts of mechanisms and machines and equipment in general. Everything is taken into account: specifics of the device and environment, temperature, physical and chemical features of lubricants themselves, equipment engineer’s guarantee maintenance terms, etc.

“The Technical Support Department provides distributors and end consumers exhaustive information about the application of a product in every case. Close contact with clients permits responding on tendencies of the market of lubricants and organise the design of solutions meeting the latest needs of consumers on time,” Agabekov highlights.

Also, TAIF-SM plans to participate in the engineering of a Russian oil classification system and approval issue. It received the approval for a line of polyalphaolefin basic oils from NSF international organisation permitting using the products in the food industry. Also, obtaining a permit from Siemens for turbine oils is one of the key news for the company. This allowed successfully starting to use oil in energy enterprises of the industry. All this permits TAIF-SM to make lubricants that can replace the assortment of oil that left the Russian market.

Satisfying consumers’ needs for the quality of highly efficient world-class lubricants and constant sales growth are the key development vector the company claims. Nowadays the R&D Centre is working on improving the existing line of products and developing new types of lubricants.

Oils by Taif Lubricants at TAIF-NK AZS petrol stations

Modern car oils made by TAIF-SM outperforming requirements of global producers in its quality characteristics have been on sale in the biggest chain of petrol stations in the Republic of Tatarstan TAIF-NK AZS since April 2021. A wide range of oils by Taif Lubricants for passenger cars and lorries are sold there. As Commercial Director of the company Nail Shaydullin notes, over the year, TAIF-NK AZS managed to successfully double the total sale of the premium line.

Taif Lubricants oils reliably protect the engine throughout its use, have improved anti-corrosion features, can be universally used at both low and high temperatures. Many clients of TAIF-NK AZS chain already managed to evaluate the quality of high-tech oils:

“After I switched to Taif Lubricants motor fuel, I noticed that the engine started to make less noise. I haven’t found any drawbacks during the use,” notes client of TAIF-NK AZS Vladimir Frank.

It is planned to expand the market, distribution network and capacities

A distribution business model was chosen to sell products of the plant of synthetic materials. Nowadays the chain has over 35 companies covering the whole territory of Russia. Distributors use products of TAIF-SM in different areas of the industry, promote motor oils for passenger cars, commercial and special machinery at the technical service station, provide supplies in the retail segment — to the shelves of federal and local chains, car spare parts stores and car dealerships. E-commerce doesn’t go unnoticed. Foreign partners promote the products in CIS countries, Asian, African, Latin American and Near Eastern states. Both the Russian market and possibilities for the expansion of exports are equally interesting and important for TAIF-SM.

Dynamically changing macroeconomic and geopolitical conditions open greater potential for development, notes TAIF-SM. New opportunities in the domestic market appear for Russian producers in different niches. And if just a year ago Russia’s only producer of polyalphaolefin oils linked prospects of further growth with exports, today the company is set to occupy leading positions in the Russian market in synthetic motor and industrial oils.

“Our every effort is put to replace imports, and in the last few months we have made sure that the demand for premium synthetic oils outruns the supply. Our team of technologists, technical specialists, marketing managers, commercial specialists have put all efforts to actively promote synthetic products, especially amid the vacant niche in the market of premium oils. In other words, we are talking about the policy of import substitution whose necessity is often discussed at federal level,” Commercial Director of TAIF-SM Dmitry Bugayev voiced priorities in the foreseeable future.

Also, the company needs big prospects in the production and sale of synthetic gear, compressor and turbine oils fully based on polyalphaolefins. Such products as TAIF VIVACE and TAIF ALLEGRO, TAIF TIRATA, TAIF INTRA LL are the special pride of the engineers in the segment of motor fuels both for passenger cars and lorries. They contain from 30% to 75% of polyalphaolefins. The work on the expansion of the line of synthetic products for a wide range of purposes goes on. And no less active job is done to expand the production capacities in general.

The goal for the next three years is to increase the production of synthetic oils to 30,000 tonnes a year. This will require expanding the capacities in oil mixing and packaging. However, the management of the company stresses that any tasks are doable and goals are attainable with such a team of professionals in the factory. A capacity expansion will require hiring new employees, and here the plant of synthetic oils focuses on attracting highly qualified staff from oil processing.

The management of the enterprise notes that the petrochemist is a traditional and main profession for Nizhnekamsk, which allows inviting qualified staff. And the company is ready to teach newcomers nuances during the work and at its own training centre where equipment from a renowned Japanese manufacturer allowing modelling both the operation of the plant’s shops in normal mode and incidents, even pre-emergencies and emergencies were purchased during the recent modernisation of production. Also, the company has agreements on staff training and retraining in specialised educational establishments.

Reference

The role of lubricant in efficacy of mechanism use

Various mechanisms have long served humans simplifying a myriad of tasks. And the requirements for lubricant increased together with the complexity of equipment, lubricant started to be added components decreasing friction — soap, alum, graphite and so on. But natural bases were capricious — they floated and even burnt at high temperatures, froze at cold temperatures. The search for effective oils and lubricants became more optical during the technical revolution in the second half of the 19th century with the launch of powerful production machine tools, pressing machines, the invention of cars, trains, steamboats and planes. Oil, gas processing and petrochemistry offered an effective method.

Oil based on hydrocarbon feedstock made a real breakthrough in the industry permitting to make a product resistant to temperatures, with low evaporation capacity, effective lubrication and the readiness to provide reliable protection of units and mechanisms from friction and corrosion. Also, such lubricants can carry off heat and pollutants from the operation area, insulate gaps between moving elements of the device, increase the efficacy and eco-friendliness of the operation of mechanisms and devices.

Today lubricants are also an effective instrument that can increase intervals between repairs with the correct selection and improve the lifespan of both separate units and parts and equipment in general, reduce energy consumption and at last improve the performance of any device.

Ad of TAIF JSC