“We should grow seven times” — Rosatom’s subsidiary and KNRTU-KAI open a laboratory of composites

The creators set a goal to increase the share of Russian composites in world production from 0,5 to 2 per cent by 2025

Umarex company (part of Rosatom) and KNRTU-KAI (Kazan National Research Technical University named after A.N. Tupolev) have opened the joint research and training laboratory Specialized competence centre Composite Technologies. The project is implemented with the support of the government of Tatarstan. Industrialists note that foreign materials, which were used in Russian production, are leaving the domestic market. But Rosatom has become to produce composites. In the created laboratory of the university, students and specialists of enterprises are trained to work on new production technologies. Read the details in the material of Realnoe Vremya.

Catch up and surpass world leaders

Composites are called the material of the present and the future. Now all kinds of its types are created for the widest application in many areas: rocket and aircraft construction, medicine, sports, construction, automotive industry. Experts say that composite materials are used not only in state defence orders, the market grows annually.

Therefore, KNRTU-KAI, which has the entire cycle of training from secondary vocational education to higher education, as well as a research centre, where they develop for aviation and rocket science, has created a laboratory of composites.

The government of the Republic of Tatarstan financed the project for 15 million rubles, the university invested about 10 million rubles, the company Umatex (part of Rosatom) — 5 million rubles, the latter also provides its materials, fabrics and films.

“The laboratory is an important point in the country for the development of the entire composites industry in Russia. This industry is one of the fastest growing in the world. The production of carbon composites is growing at more than 11 per cent per year. By 2025, their world market will increase by 2,5 times. Our common goal is to increase the Russian market of composites from 0,5 per cent in world production to at least 2 per cent by 2025, which means that we are to grow seven times,” said the CEO of Umatex Alexander Tyunin.

Tyunin considers the training of professional personnel, who can be trained on the basis of such centres, as the main resource of development of technologies. He reminded that in 2012 the government of Tatarstan and Rosatom signed an agreement on the construction of a plant for the production of the most advanced carbon fiber, which was successfully launched in 201

“We are building a modern enterprise for the production of raw materials for carbon fiber, which will allow to catch up with the world leaders in the line of modern carbon fibers by 2021,” said the director of Umatex.

“The president sets the task to make educational institutions and the industry closer to each other. The composites laboratory is a key area for our enterprises to be competitive, given that our aircraft industry is developing, and companies in SEZ Alabuga are engaged in the manufacture of composite fiber. With the help of such centre, industrialists will have the opportunity to obtain personnel for the production of modern products,” stated Minister of Industry and Trade of Tatarstan Albert Karimov.

According to him, in the presence of an educational cluster, industrial producers and consumers of composite fiber, such a comprehensive complex for the production of composite will allow all added value to be kept in the republic.

The Chinese are already working, the Ukrainians are next

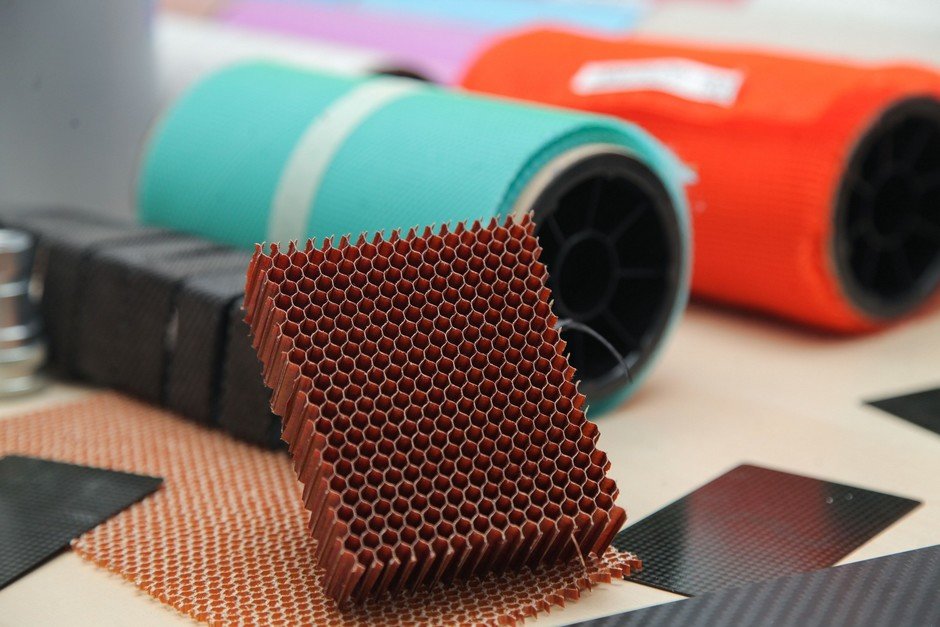

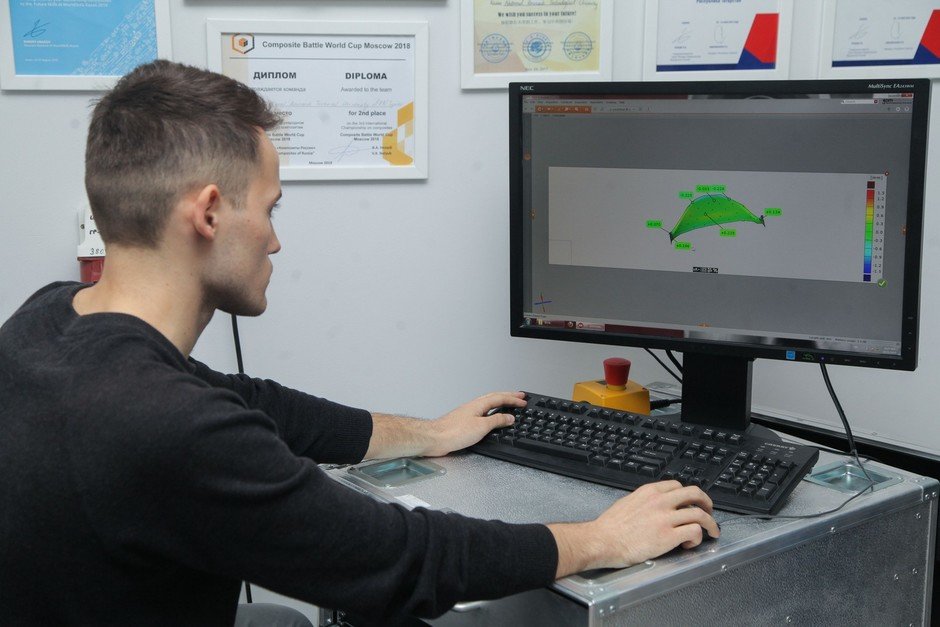

The research and training laboratory is already working. According to WorldSkills expert and head of the laboratory Arseny Polyaev, the centre recreated in miniature the full cycle of composite production from modelling and design to the control of parameters and the section of cutting and laying out the material. Laboratory equipment is mobile, it can be transported to various sites. Here they make out-of-gauge products for real drones.

“Designers come here who can draw, but at their factory they can not see their product immediately. Here they model, immediately go to the machine, make, see their mistakes. We adjust their work, teach the technology. There are designers of the senior age category who worked with metals. But with composites — a different principle of work, they also need to learn. Here they gain not dry knowledge given at university, but model, get the qualification,” said Arseny Polyaev.

Kazan specialists will be trained in the laboratory before the WorldSkills regional championship. Not the first time it turns out to work with composites from specialists with certain skills. Now Chinese engineers are trained in the centr, they do not have the opportunity to develop designs and work out all operations at their enterprise — for this, specialists from China go to Russia. A group from Korolyov is coming next week in Kazan. In turn, other Chinese are next, Ukrainian enterprises are also interested.

Rector of KNRTU-KAI Albert Gilmutdinov considers the task to make the laboratory self-supporting quite real. The capacity of the centre is 600 people a year with a 40-hour programme a week.

There are not enough workers, especially in composite industry

Albert Gilmutdinov stressed that the laboratory, which was created by representatives of the three parties, is an excellent example of public-private partnership. He also introduced the fourth participant of this cooperation — AeroComposite company. The plants of this enterprise, the consumer of composite materials, are located in Moscow, Kazan, Ulyanovsk. Now Russia is working on a medium-haul passenger aircraft MS-21. In the wing and tail of this machine, a lot of composite elements is used, which is produced by AeroComposite.

“We can buy equipment, find a consumer, but the problem with training remains. We are thankful for such projects and are ready to provide its production facilities for practice by students,” said Director General of AeroComposite JSC Gaydansky.

“The composite industry is not attractive for graduates of technical universities. It is very difficult to find a specialist who has basic knowledge and skills in composites. The company is experiencing a personnel shortage,” confirmed the representative of the Kazan Plant of Fiberglass Pipes Marsel Akhmadullin.

The head of the research department of the Samara National Research University, Albert Gareev, believes that “it was necessary to create such a laboratory a long time ago”:

“There are a lot of engineers, and we do not have enough workers, specialists in enterprises. KNRTU-KAI team — it is very strong researchers in scientific terms. They are ahead, I think many universities will pick up. Here we can introduce new things, develop technologies and train young people. The composite laboratory will integrate higher technical education and production, accelerate the economy and give a dynamic impetus to its development.”

In conclusion, Albert Gilmutdinov and Alexander Tyunin signed an agreement on the inclusion of KNRTU-KAI in the interregional industrial cluster Composites Without Borders. As the rector of the university noted, de jure such signing will allow the university to integrate into a large industrial complex, open the doors to the market of new educational and technological services.