Kazanorgsintez in 2016: record-breaking revenue and new projects

Enterprises of the petrochemical complex of Tatarstan increased production volume by 4.4% in 2016. A considerable contribution to this growth was made by Kazanorgsintez (KOS), which increased production and gained a record-breaking in the history of the enterprise revenue at 75.4 billion rubles. The company made it possible due to the active work with consumers of the products and favourable conditions in the domestic and foreign markets. Realnoe Vremya has analysed the results of the work of the enterprise by studying the company's annual report. Director General of Kazanorgsintez Farid Minigulov gave his assessment of the work speaking at the annual meeting of the shareholders.

Growth indices

''Last year we were actively engaged in improving product quality, enhancing resource efficiency and reliability of the equipment,'' said Director General of the company Farid Minigulov, evaluating the economic-financial performance. ''However, the lack of gas feedstock and, as a consequence, incomplete loading of capacities on the manufacture of polyethene, have not allowed us to increase commodity production significantly. Nevertheless, the physical volume index to the level of last year amounted to 104.1%. The volume of produced commodity output exceeded almost 988.000 tonnes. Cost reduction, active work with consumers of our products, favourable conditions in the domestic and foreign markets have allowed us not only to perform the planned production volume but also to achieve a positive dynamics of financial indicators.''

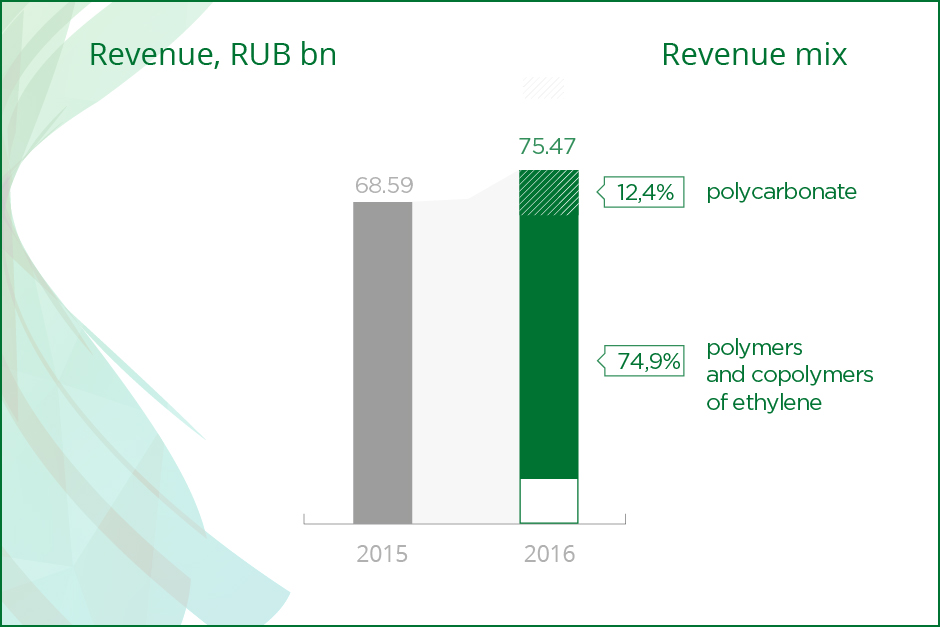

One of the signs of the effectiveness of Kazanorgsintez is a growth of capitalization of the enterprise by 28.26% to 77.6 billion rubles. The high financial stability is confirmed by the increase of the equity capital by almost 35% to 47,50 billion rubles. Competent marketing policy of the enterprise and high prices of polymer products have become the main drivers for the revenue growth of Kazanorgsintez PJSC. It increased by 10% and amounted to 75.4 billion in comparison with 2015. The revenue mix was virtually unchanged compared to the previous year: more than 90% are the main products of the company — polyethene, polycarbonate and polyethene pipes.

Despite the growth in revenue, the net profit of Kazanorgsintez a little decreased — from 19.29 billion to 18.17 billion rubles. This decline is due to incresed costs of the enterprise. The cost of sales increased by 11.2% and exceeded 48 billion rubles. This cost increase is an objective factor, it is associated with rising prices for raw and other materials, as well as with higher rates and prices for energy resources.

The growth of revenue, sales and wage fund increased tax payments of Kazanorgsintez. Payments to all budget levels in 2016 accounted for 12.45 billion rubles (a growth — 19.2%), including to the consolidated budget of Tatarstan at 6.23 billion rubles.

Good financial results allowed Kazanorgsintez to fully perform the obligations under the credit agreements. As on 31 December 2016, the debt decreased to 5.91 billion. ''Another proof of stable financial results and the sustainability of our business is the increase in 2016 of the long-term rating of Kazanorgsintez at the international rating Fitch from B- to B,'' said Farid Minigulov. ''Already in February 2017, the rating outlook changed from ''stable'' to ''positive''.

Increasing export

Kazanorgsintez annually produces and sells more than 170 items of various chemical products such as polyethene, polycarbonate, polyethene pipes, bisphenol, phenol, acetone, ethylene glycol, ethanolamines and other products of organic synthesis. Today, the share of enterprises in total Russian production of polymers and copolymers of ethylene is 43%, of ethanolamines — 40%, acetone — 34%, phenol — 32%, polyethene pipes — 10%. Besides, Kazanorgsintez is the only Russian manufacturer of polycarbonate.

''Improving and modernising logistics processes at the enterprise, we are aiming to expand the presence of our products in new geographic markets, developing mutually beneficial international cooperation with foreign partners,'' Director General of the company explains the export strategy.

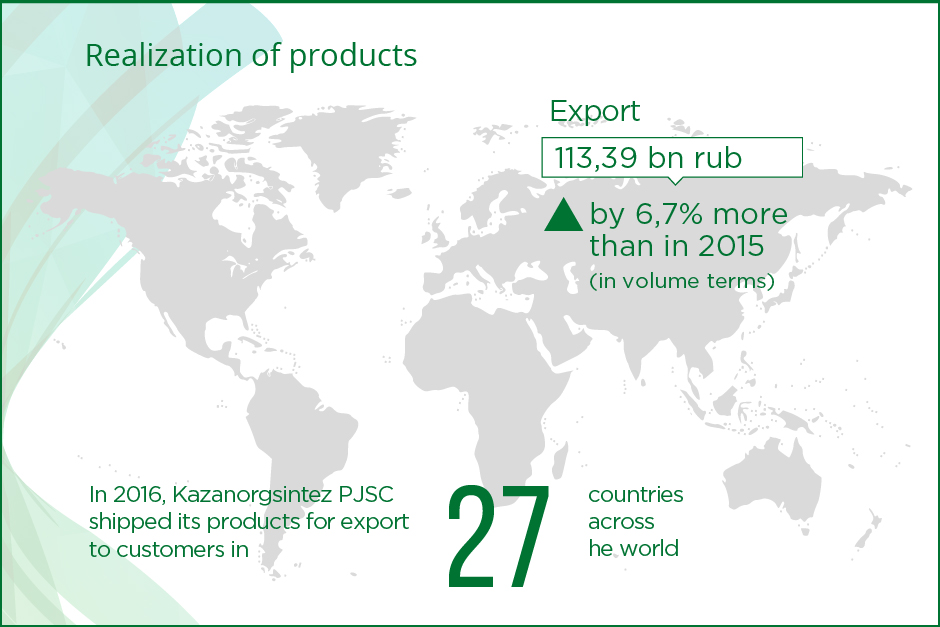

Last year, KOS exported products at 13.4 billion – it is 6.7% more than in 2015. The export is primarily focused on the countries with a higher level of contract prices. The sales network is constantly expanding, increasing the share of its presence in the markets of basic products. Now about 1.000 companies from 27 countries are customers of the products of Kazanorgsintez. Israel, Nigeria have become new export markets. Also, the supplies of products to Moldova, Italy and Switzerland have been resumed.

The modernization continues

Kazanorgsintez is constantly working on upgrading the equipment. Thus it achieves a significant savings of material and energy resources, increasing production and improving logistics.

Within the framework of the plan of major investment activities of Kazanorgsintez PJSC for the period 2013-2016 on the activity stabilisation and maximum load of production capacity, during the year it was provided the stable work and expanding the raw material base for the production of ethylene and high-density polyethene (HDPE). The operation of two-chambered pyrolysis oven Technip, which was launched in December of 2015, showed the effectiveness of the project. KOS increased its production of own ethylene, including by processing of propane fraction. For further increase of efficiency of use of raw materials and increasing production capacity of ethylene in 2016, it was signed a contract with Technip for the supply of three more ovens for pyrolysis. The introduction into service of the ovens is scheduled at the end of 2018.

Also, at the plant Ethylene, the construction of the plant of pressure swing adsorption was completed and commissioned. The plant will provide the productions of KOS with hydrogen in the required quantity and of consistently high quality. At the plant of low-density polyethene in the shop of plastic products, there was commissioned the division of packing, palletizing and shipment of polyethene. In total, 5.71 billion rubles were allocated for the investment of capital construction objects, as well as to replace and upgrade equipment in 2016.

Effective energy saving

An increase in production volumes is impossible without implementation of energy efficient activities that minimise energy consumption and maximise the use of recyclable and renewable resources.

Kazanorgsintez operates the program of energy saving and energy efficiency in 2011-2015 and in prospect by 2020. In 2016, there continued the implementation of energy saving and energy efficient equipment and materials, allowing to reduce the cost of consumed steam from the external source, Kazan CHP-3, and to increase its own production of steam.

Besides, the divisions of Kazanorgsintez PJSC replaced obsolete and outdated lightning fixtures with energy-saving led ones. As a result of all activities, the energy intensity of commodity products decreased by 9.7%.

The economic effect from the implementation of the energy saving program in 2016 amounted to 200 million rubles. In just 6 years of the ''Long-term program of energy saving for 2011-2015 and in prospect by 2020'', the company has saved more than 980 million rubles.

As for the future development, Kazanorgsintez continues the development of the concept until 2025. In this document they elaborate the issues of raw materials supply and discuss options for increasing capacity of production of ethylene, polyethene and other areas of petrochemical production based on the processing of ethylene.