Equipment wear and personnel shortage: problems of Tatarstan’s metalworking industry

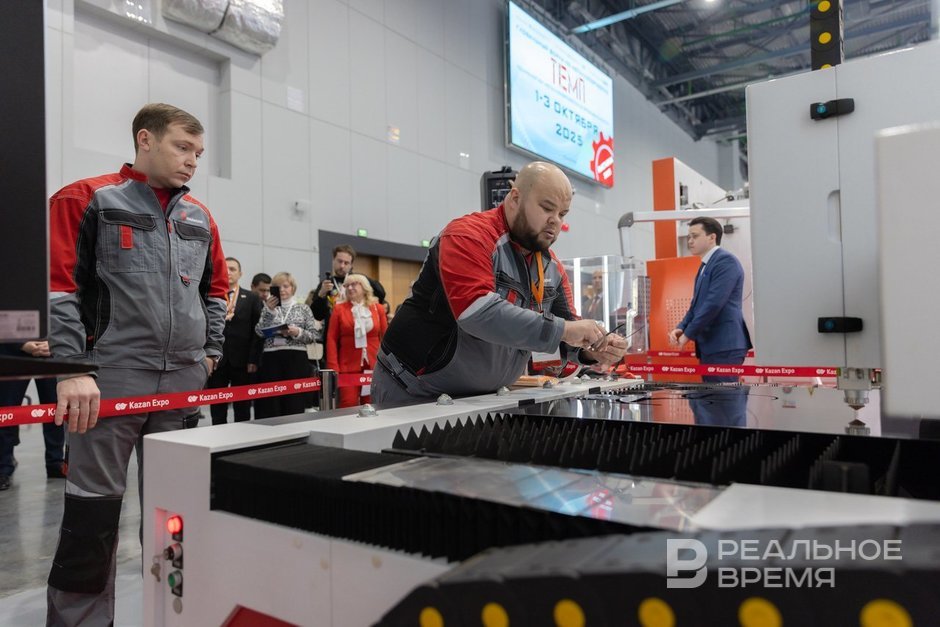

More than half of the equipment in the Russian machine tool industry is worn out — the operational status of some of it exceeds 25 years. The share of machines up to five years old is only 4.7%. At the same time, the issue of personnel shortage is acute; the country is critically short of welders, fitters and mechanics. However, despite the problems, production is only gaining momentum — over a year, the volume of the Russian machine tool market has grown by almost 45%. Experts spoke about this situation at a plenary session of TEMP Global Metalworking Forum on Metalworking. Read more details about the situation in the mechanical engineering and metalworking sector in a report of Realnoe Vremya.

“It's too early to rejoice”

“Import substitution has become a natural and dynamic process,” read the presentation by head of the Tatarstan Investment Development Agency Taliya Minullina. At the plenary session of TEMP Global Metalworking Forum, she announced the layout and interim results of the work of the mechanical engineering and metalworking sectors of the republic.

Thus, the share of Russian products in the domestic market has reached a record high. In transport mechanical engineering, the level of import substitution is 97%, in energy — 77%, in oil and gas — 54.5%, in heavy — 52.4%.

“Of course, it is written beautifully that import substitution has become a natural and dynamic process. And this is really so. But it is too early to rejoice, because we still have a lot of products that have not been substituted. We have partially replaced Western players, but nevertheless, the technological potential is still high,” Minullina commented on the situation.

Investments in fixed assets of Tatarstan for the first 6 months of 2024 amounted to 521.5 billion rubles (438.2 billion rubles excluding budget funds). Of the total amount, 10.8% falls on mechanical engineering and metalworking — that is, about 52 billion rubles.

In general, there is a tendency towards an increase in the volume of investments in fixed assets. Thus, in 2020, the amount amounted to 605.8 billion rubles (544.2 billion excluding budget funds), and by 2023 it reached 1.2 trillion rubles (953 billion excluding budget funds).

Such work led to an increase in the gross regional product — last year, it totalled more than 4 trillion rubles. Over three years, the indicator has almost doubled, added the head of the agency:

“This is a very serious growth. We have not seen such dynamics in the last 10 years. Investments in Russia are also growing, including in the metalworking sector. Limited access to financing and barriers that our country has, the pressure of sanctions worked to activate the domestic economic situation and led to the development of our own production.”

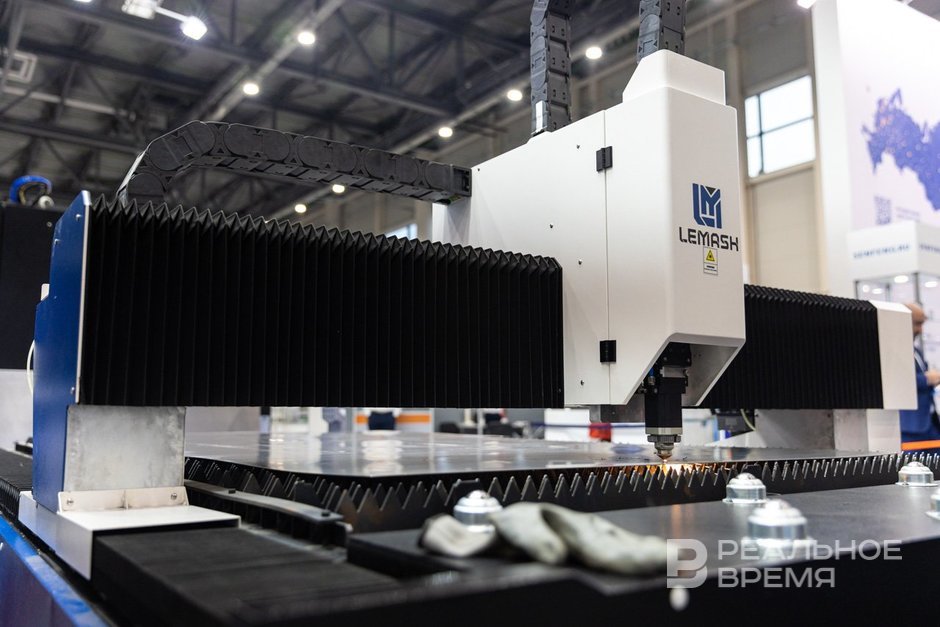

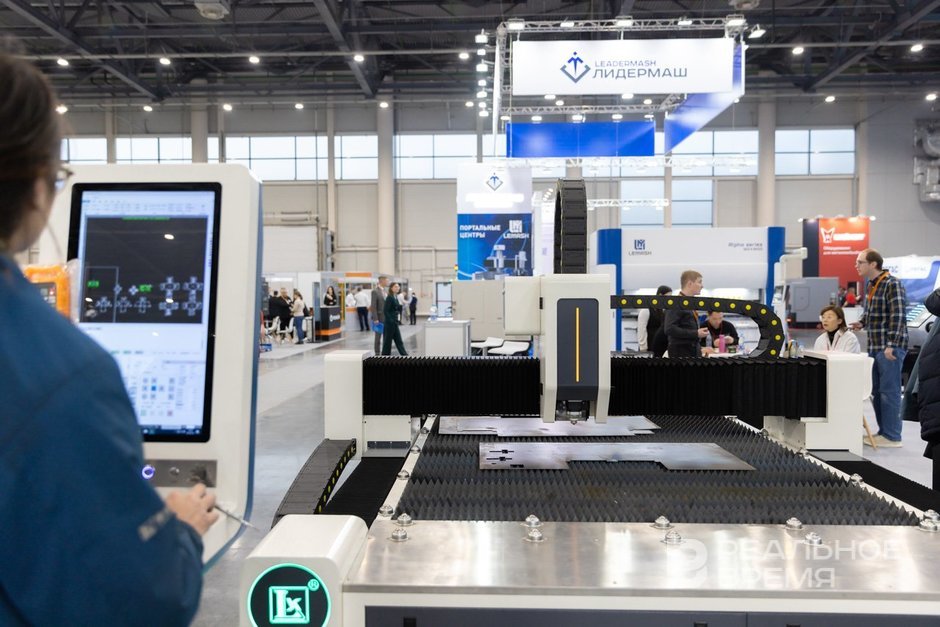

More than half of the equipment is worn out

As for the all-Russian market, by the end of 2023, production reached 142 billion rubles. Every year, the country produces machine tools for a total of 31 billion rubles. This was reported by Deputy Director General of Broadcasting TNV channel, moderator of the event Svetlana Kadyrova.

According to her, production volumes are only growing. For example, according to estimates for 2023, in the mechanical engineering industry on the external market, the volume of shipped products increased by 25% and amounted to 1 billion 56 million rubles.

Turning machines remain the most in-demand today — 35% of the market volume. Next come milling (25%) and grinding (24%) machines.

However, more than half — 63-65% — of the equipment in the industry is worn out, Kadyrova added:

“Many manufacturers use machines whose operating status exceeds 25 years. At the same time, equipment with a service life of up to 5 years makes up only 4.7%.”

Critical shortage of personnel

Another acute problem in the industry has become the already painful issue of personnel shortage for Russian industry. Training young specialists has become the goal on the path to restoring the country's industrial sovereignty, said moderator Svetlana Kadyrova.

“Industrial enterprises, in particular the metalworking and machine tool industries, need personnel the most. According to the service for the selection of engineering technical personnel, the country is critically short of welders, fitters and mechanics,” she explained.

According to her, enterprises that are looking for specialists interested in raising the level of Russian industry have several ways to attract valuable personnel.

The first is to turn to the state for help. It is necessary to organise a production cluster. Then there will be a chance not just to find a workforce, but specialists who really know the internal processes of enterprises.

So you can also raise wages and compete for valuable personnel. However, according to Kadyrova, things are not so clear-cut here:

“This method will work if the company needs to retain a valuable or even irreplaceable employee. However, in this way you can attract young people who are now looking for themselves.”

Another way is to train students at universities and colleges. They conduct a curriculum that is fully adapted to the realities of manufacturing enterprises.

“Rostec Wings project is a good example of this joint training. This is an educational project of Rostec state corporation to train engineering personnel for the aircraft manufacturing industry,” Kadyrova shared.