Five stages of quality control at TAIF-NK Gasoline Plant

More than half a million tonnes a year, or every fourth liter, of motor gasoline in Tatarstan is produced at TAIF-NK

There is hardly a car owner in Tatarstan and neighbouring regions of the republic who would not be familiar with bright, modern filling stations equipped with branded colours with a winged leopard. And those who managed to estimate the quality of the fuel sold at these stations become regular customers of TAIF Group's branded network. But how is the quality control of gasoline carried out, whether only the Volga region is familiar with it, and finally, who, where and how produce it, and whether the list of products is limited to gasoline only? About all this — in the continuation of the cycle of the materials of Realnoe Vremya about the history of TAIF-NK oil refining complex.

According to the latest science and technology

Acquaintance with the production process of the Gasoline Plant of TAIF-NK JSC for the journalist of Realnoe Vremya began with the laboratory. And it is logical. The five stages of quality control are not just words. According to the head of the laboratory, Olga Kalacheva, at each stage, the nuances of processing technology depend on the verdict of her subordinates.

“The first stage is quality control of raw materials — vacuum gas oil and gas condensate. By the results of laboratory tests, the quality of processed raw materials is determined, the need to make adjustments to the maintenance of the technological regime to increase the conversion rate of processing," she said in an interview.

The level of equipment of the laboratory is impressive: gas chromatographic complexes, sulphur analysers, fractional composition analysers, density metres, titrators, octane number determination unit, atomic absorption spectrophotometer for determining the content of metals — this is not a complete list of equipment of domestic and imported production necessary for comprehensive and full-scale tests. There are dozens of units of modern measuring equipment in total, each of which has its own purpose and tasks. About 100 qualified laboratory specialists at two production facilities in several shifts (at all stages of production) carry out constant monitoring for compliance with the established parameters and the required level of quality of petroleum products. More than 42 thousand samples are analysed a year for 140 thousand indicators. Each test can take from 20 minutes to 4-6 hours.

“Over the 17 years that have passed since the foundation of the laboratory, the requirements for the quality of refined petroleum products in general and motor gasoline in particular have significantly tightened. Especially in terms of environmental requirements. We control the processes at all stages of production until the time of shipment of finished products. At the moment, the passport of our motor gasoline contains 18 indicators in accordance with the requirements of the regulatory document and four additional indicators," explained Olga Kalacheva.

No less attention is paid to other types of gasoline plant products: straight-run gasoline — raw materials for further processing at petrochemical enterprises of Tatarstan, diesel fraction, fuel oil, liquefied petroleum gas.

Another important mission assigned to the laboratory's specialists is research:

“We are engaged in testing not only in relation to the quality of commercial products, but also carry out research on various octane additives, components of gasoline, corrosion inhibitors and absorbers of hydrogen sulfide and mercaptan sulphur. Only after such laboratory tests can innovations be scaled into production technology. In laboratory conditions, it is determined how additives affect the quality of the final marketable products — gasoline," the head of the laboratory of the gasoline plant emphasised in a conversation with the journalist of Realnoe Vremya.

The quality of the laboratory of the gasoline plant of TAIF-NK JSC is also evidenced by that according to the results of the republican contest “Best Goods and Services of the Republic of Tatarstan”, it was recognised as one of the best in Tatarstan in 2020.

Gasoline that prolongs the life of the car engine

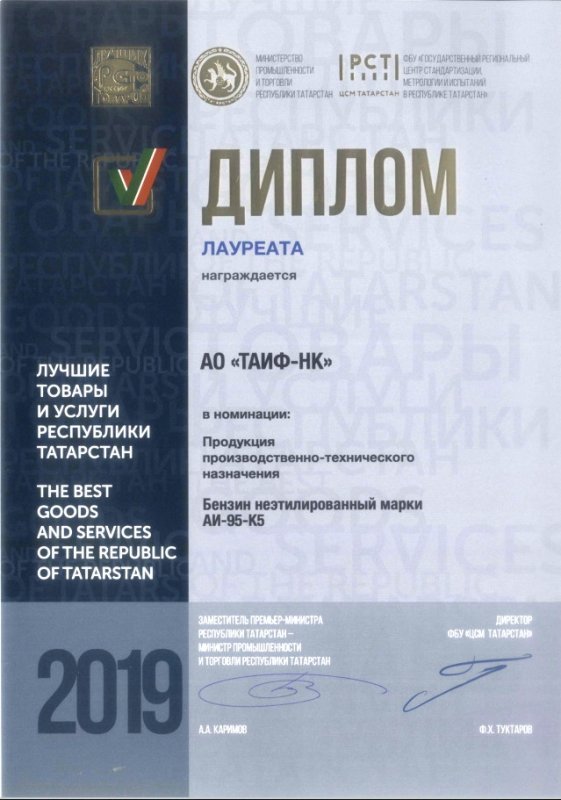

The products of the Gasoline Plant of TAIF-NK JSC have been repeatedly recognised as the best. The evidence of this is numerous diplomas of republican and federal quality competitions. A significant part of the awards went to the most mass-produced product — automobile gasoline.

However, the compliance of gasoline from TAIF-NK with the requirements for automotive fuel is constantly confirmed by independent experts. In Tatarstan, the quality of products sold at the filling stations of the republic is monitored on a regular basis. The raids are organised by specialists of the Management of Rational Use of Fuel and Energy Resources GBU.

Back in 2015, ahead of the deadlines set by federal requirements, the TAIF-NK Gasoline Plant completely moved for the production of automotive fuel of the Euro 5 standard and today produces motor fuel only of this class — meeting the most stringent global environmental requirements.

For information: sulphur content in gasoline mg/kg:

- Euro 2 — up to 500;

- Euro 3 — up to 150;

- Euro 4 — up to 50;

- Euro 5 — up to 10.

As the director of the Gasoline Plant, Ilsur Samigullin, admitted, he himself is a fan of their own products. And for this, as a motorist with a solid experience, he has reasons:

“For sure, many car owners at the filling stations of some other manufacturers paid attention to the signatures on the columns with 92 or 95 gasoline: “the fuel contains such and such additives for flushing the engine from carbon deposits”. It is not necessary to do this with our gasoline, since it does not form carbon deposits. At all. Hence the benefit: long-term use of gasoline from TAIF-NK prolongs the working life of the car as a whole. When using other gasoline for 5-10 years due to carbon deposits, the car will still require expensive maintenance. This does not happen on our gasoline. I use our gasoline myself. You always need to look at least a few steps ahead," he shared his personal observations with the journalist of Realnoe Vremya.

Aleksey Khramov, the chief engineer of TAIF-NK JSC, is also a fan of the products of his native enterprise. According to him, with equal requirements for motor fuel, gasoline from different manufacturers, a knowledgeable person will easily be able to distinguish from each other. They, like human fingerprints, have a different component composition. And without false modesty: TAIF-NK has something to be proud of.

“It is clear that we, like other refineries, produce commercial gasoline today only according to GOST. But the component composition of the gasoline produced by TAIF-NK contains many times less substances such as resins, aromatic hydrocarbons. The low content of these substances leads to a more complete combustion of the fuel-air mixture and, as a consequence, to the absence of coking of engine parts. In other words, both in terms of performance and environmental friendliness, TAIF-NK gasoline can already be called branded today," he stressed.

Not just gasoline

“Gasoline Plant”. Almost everyone who hears the name of the company will be sure that the production is entirely focused on the production of gasoline, and ... will be mistaken.

The plant itself consists of two productions. The first is the oldest. Once upon a time, outdated equipment of Nizhnekamskneftekhim stood on this place. In 2001, it was dismantled, and the only catalytic cracking unit in Russia and the world, built using Russian technology, stretched to the sky in the vacant place. In 2006, the first batch of products was already produced.

Shamil Zaynagutdinov is the head of the catalytic cracking shop, has worked here almost since the first days. In 2001, he came as a young operator of the 4th category, took part in the dismantling of old equipment, then in the construction of the first gasoline plant in Tatarstan. Now he runs his own workshop. He notes that it is more than realistic for those who are not only ambitious, but also hardworking, proactive and responsible to climb the career ladder at TAIF-NK. He is a living example of this himself. But we will talk about the people working at the gasoline plant and the opportunities that open up to them in the next part of the cycle. As for the installation of catalytic cracking, it is not for nothing that it is called the “heart of the enterprise”.

“The unit is designed to produce gasoline from vacuum gas oil and fuel oil, dry gas — fuel for furnaces of its own production, propane-propylene fraction, butane-butylene fraction. The propane-propylene fraction goes as a raw material to Nizhnekamskneftekhim, the butane-butylene fraction is also partly sent to the petrochemical complex, and partly becomes a raw material for the installation of obtaining methyl tert-butyl ether (MTBE) from the isobutylene contained in it — an octane—boosting additive. Another type of octane-boosting additive — tert-amyl-methyl ether (TAME) — is produced from isoamylenes contained in the light gasoline fraction, also obtained at our catalytic cracking plant. Additives of own production are used in the production of 92nd and 95th grades of gasoline. We also get light gas oil, which goes to the refinery as a raw material for producing diesel fuel. And we get heavy gas oil, which goes as raw materials to the carbon black plant," Shamil Zaynagutdinov briefly listed the main types of products produced in the workshop he heads.

The construction of the second production of the gasoline plant — a gas condensate processing plant — started in 2005. With a raw material capacity of 1 million tonnes a year, today the workshop produces straight-run gasoline — the main raw material for the neighbouring Nizhnekamskneftekhim, diesel fraction and fuel oil, which serves as raw materials for the first production of the gasoline plant, liquefied petroleum gases and kerosene.

And the same production includes a drain-filling double-sided gallery overpass with railway scales, an automobile automatic filling station and a complex of general factory facilities with a compounding unit and a fleet of commercial gasoline. In other words, it is here that raw materials are received for further processing, and from here the finished commercial products of the gasoline plant are sent to consumers.

By the way, the company's responsible approach to environmental issues is also noticeable here: in 2019, the gasoline vapor recovery unit was completely re-equipped, which now almost completely eliminates fuel vapours entering the atmosphere during its shipment.

Domestic market is a priority

And in the previous years, which were quieter in geopolitical terms, TAIF-NK JSC focused on providing domestic consumers with its products. Now, in the context of unprecedented sanctions pressure on Russia from the collective West, the correctness of the chosen approach has become obvious. It turned out to be a far-sighted and correct decision that at one time TAIF Group invested heavily in the creation and continues to actively invest in the development of its own network of branded gas stations in Tatarstan and operating in a number of neighbouring regions.

“We fully satisfy the needs of our gas station network with high-quality gasoline of our own production. At the moment, our gas stations cover about 45-50% of the total volume of our production of gasoline of the 92nd and 95th brands. The rest of the gasoline is sold on the domestic market of Russia, including significant volumes — through the St. Petersburg Commodity Exchange. We fully comply with the recommendations of the Ministry of Energy of Russia to domestic refineries for the sale of at least 12% of production volumes at exchange auctions. Gasoline from TAIF-NK is supplied to the regions of the Central Federal District, the Volga region, there were sales up to the Far East. The geography is constantly expanded, as well as the circle of consumers. These are traders, oil depots, sole proprietors, third-party large gas station networks, etc.," Deputy General Director — Director of Commerce of TAIF-NK JSC Artem Shcherbina said in an interview with Realnoe Vremya.

According to him, gasoline from TAIF-NK is attractive to consumers for many reasons. But at the forefront is the consistently high quality and high level of responsibility of the Tatarstan refinery, which strictly fulfills the terms of contracts and strictly maintains the agreed terms of shipment of products to consumers.

To be continued.