About how petrochemists of Kazan replenish fish stock in Kuybyshev Reservoir

Ecological measures of Kazanorgsintez spent over 115m rubles in 2015

Seven technologically independent enterprises, which produce over 170 types of products, are situated on the territory of Kazanorgsintez, one of the largest chemical enterprises of Tatarstan and Russia. Ecological properties are the obligatory component of quality and competitiveness of these goods. In addition, the Sanitary and Industrial Laboratory of KOS constantly controls the state of atmosphere, the quality of wastewater spewed out into the Volga River and pollution of soil. It allows to monitor the ecological situation in the zone of the enterprise. The laboratory carried out about 34,600 different analyses only last year. A correspondent of Realnoe Vremya looked into the systems of ecological management of the one of the giants of the sector.

Intense growth without ecological harm

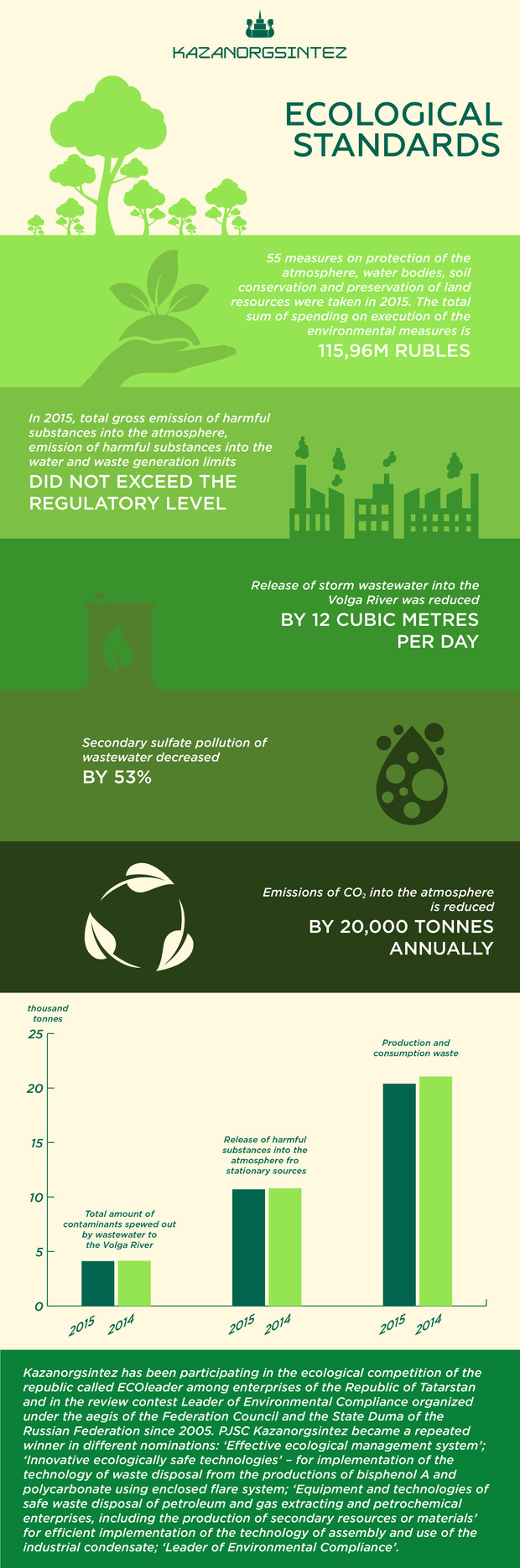

Further intense growth was marked as a strategic development programme of PJSC Kazanorgsintez. But this growth is impossible without following ecological regulatory levels. The system of ecological management has being applied in the enterprise since 2005. There is an ecological policy, and plans on environmental measures is elaborated annually within the scope of the system. According to the deputy head engineer and head of the Department of Ecology of PJSC Kazanorgsintez Andrey Smolko, in 2015, 55 measures on protection of the atmosphere, water bodies, soil conservation and preservation of land resources were taken in 2015. The total sum of spending on execution of the environmental measures is 115,96m rubles. Funds of Kazanorgsintez were used for all spending.

These investments yielded a fruit. In 2015, total gross emission of harmful substances into the atmosphere, emission of harmful substances into the water and waste generation limits did not exceed the regulatory level.

Modernization of the production technology of diphenyl carbonate in Polycarbonate Plant, when a titanic catalyst danger class IV was used instead of leaded catalyst that has a danger class I. This substitution makes the manufacture safer and allows to reduce the production of secondary products from polycarbonate products and decrease the consumption of energy resources and raw material. The cost of the project was over 58m rubles.

Without greenhouse gases

The company implements advanced technologies and elaborates measures that allow to reduce the emissions of greenhouse gases. The main emissions of greenhouse gases are the result of disposal of vent emissions in ethylene and polyethylene production in flare facilities; when natural gas is burnt in pyrolysis furnace in ethylene production, in the facility for liquid effluents disposal; when automobiles burn fuel; when wastewater is biologically purified.

Now all emission sources of PJSC Kazanorgsintez emit about 120,000 tonnes of greenhouse gases per year. Emissions of CO₂ into the atmosphere is reduced by 20,000 tonnes annually as a result of realization of a project on use of flare vent emissions for the production of liquid carbon dioxide – a raw material for polycarbonate production. In addition, they generated 227,720 Gcal of secondary steam for the needs of the enterprise.

So, KOS follows the Kyoto Protocol that commits to reduce greenhouse gases emissions. In PJSC Kazanorgsintez, there are measures on energy conservation and increase of effectiveness for 2011-2015 and till 2020 which, consequently, will enable to reduce indirect greenhouse gases emissions by about 1m tonnes.

There is another example of ecological safety measure: waste disposal from the productions of bisphenol A and polycarbonate using enclosed flare system that allows to burn liquid effluents danger class I – tarry residues of bisphenol A to 3,600 tonnes per year, so that the burning is not visible, the zone is smokeless, noise level is low, and there is not thermal radiation. And transfer in Ethylene Plant to the flare system allowed to reduce emissions of saturated and unsaturated hydrocarbons into the atmosphere by 30%.

Effective water cycle

All polluted industrial, storm and domestic effluents of Kazanorgsintez are purified in wastewater treatment plants in the shop of neutralization and purification of storm wastewaters where waters are exposed to separate mechanical and combined biological treatment. The company uses many novelties in this process.

Secondary sulfate pollution of wastewater decreased by 53% and volumes of storage and consumption harmful sulfuric acid in the shop of neutralization and purification of industrial wastewater reduced by means of the implementation of the neutralization technology of alkaline waste using their own carbon dioxide produced by the enterprise. It favours the improvement of conditions of occupational health and safety and increases the flexibility of regulation of the very process of neutralization.

Kazanorgsintez uses up-to-date technologies to increase the effectiveness of use of circulating water. Works on design and installation of PALL system of microfiltration were carried out in biological treatment plants. Now storm wastewaters return to the technological process. Release of storm wastewater into the Volga River is reduced by 2m cubic metres per year. The quantity of water withdrawal from the river for system charge has the same indicator. The enterprise managed to reduce the emission of wastewater due to the implementation of the scheme of return of scouring water of filter, sinker and the centre of sediment dehydration in the shop of the wastewater treatment plants and external communications (water withdrawal).

Several projects were consecutively carried out in the steam supply plant. The project on facility for production of chemically purified water for ethylene productions using steam condensate. Putting the equipment into operation enabled to increase the reliability of chemically purified water supply to factories, reduce operational costs on preparation of chemically purified water compared to the costs on preparation on partially salt-free water that was used earlier and additionally produce own steam using Technip pyrolysis furnace of Ethylene Plant. KOS also achieved an ecological effect: consumption of water of Volga has been reduced, and wastewater emissions decreased to 1,8m tonnes per year.

The company worries not only about prevention and minimization but also compensation of the harm done to nature. In recent years, Kazanorgsintez takes measures on replenishment of fish stock in Kuybyshev Reservoir. For instance, over 276,000 of young starlets, bighead carps and common carps at 4m rubles were released to the reservoir.