How much weight will Ansat helicopter lose in Composite Battle?

Three-ply hatch in the engine part of the Ansat helicopter is to be designed and made by 10 teams of the federal stage of the world championship Composite Battle-2016, which has recently been opened in Kazan. Whose hatch will be lighter, hence cheaper — they will go in to the international final the Composite Battle World Kazan-2016. Tatarstan presents two 'production' teams of young specialists from the Kazan Helicopters plant and KAPO-Composite.

Why not a wing

From a variety of options, the organizers of the Composite Battle 2016 have chosen the model of a hatch of the lightest in Russia Ansat helicopter.

According to the deputy director of the intersectoral engineering center 'New materials, composites and nanotechnology' Ilya Chudnov, its design has a small size — from 500 to 300 mm and, therefore, does not require a lot of expensive composite material for its manufacture. The teams are to assemble 10 hatches with a streamlined shape.

'If we chose a wing, how would the commission of experts test a product in practice?' he smiled. According to him, a product will participate in the competition only if that aircraft design will not 'fall apart' and will bear the performance characteristics. Then a product will be evaluated on the accuracy of the geometry, strength, rigidity and weight. The lighter, the better. Because every 'lost' kilogram reduces the weight of the airplane and helicopter, and this is one of the main advantages of the design. For the sake of this, aviation was the first to change heavy metal to a lightweight composite.

Russia is an uncharted territory, we should develop these markets

'A hatch of fragment of the Ansat fairings is not a resource unit, but rather a complex three-ply element. The abilities of a technologist and designer are revealed when designing and making it,' added the vice rector for scientific and innovative activity of Kazan National Research Technical University Sergey Mikhailov. 'A challenging job await the guys, who will gather at the milling machines.'

'The aim of the championship is to show people that the composites can be used not only in the sophisticated military machinery but also in the national economy at all levels. The Russian market occupies only 1% of the global production of composite materials. Russia is an uncharted territory, we should develop these markets,' added Chudnov.

KAPO-Composit and Kazan Helicopters send fighters

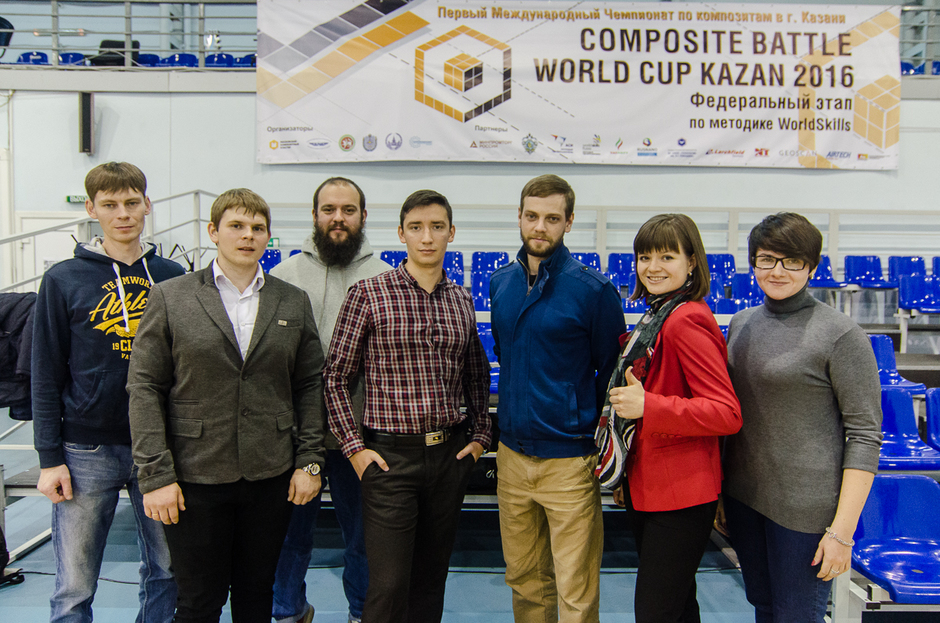

Ten Russian teams will take part in the federal qualifying stage of the Composite Battle-2016, which will be evaluated by the standards WorkSkills. Among them — student teams of the MSU, the Moscow Aviation Institute, the Samara National Research University, the Southeastern University, as well as the teams of young experts of the Ruskompozit, ONPP Technologiya named after Romashin, the research institute Graphite. Tatarstan presented two 'production' teams of young specialists of the Kazan Helicopters plant and KAPO-Composite.

In total, the competition will involve 50 young people under the age of 35. Within three days, they are to develop a drawing, to prepare tooling, to make elements of a hatch and to assemble them. The expert jury will carry out tests independently. The main task of the contestants is to enter top five winners to get a chance to participate in the finals of the international championship.

This year, the assessment form of the participants of the championship has markedly complicated. According to the deputy director of the intersectoral engineering center 'New materials, composites and nanotechnology' Ilya Chudnov, among the important evaluation criteria there has been introduced the index of tangible labour costs. 'They will give statements with calculation of the materials used. All costs will be taken into account. The less you have, the higher the score,' he told to the participants.

The expert of the Samara team Valery Komarov, the director of the Institute of aviation designs of the Samara National Research University believes that due to introduction of the 'economic' scores the work of experts has significantly complicated. 'The idea is not bad, but, as mathematicians say, there is the 'curse of dimensionality'. Because there are a lot of teams — for each component of the product and for each type of work we will have to do evaluation in many positions. 10 teams, then you need to give 500 scores in three days. It's too much. Four main scores would be enough: the surface quality from the point of view of aerodynamics, strength, rigidity and weight. The weight is associated with the price, because the materials are very expensive. The economy can be indirectly counted through weight — to put on the scales and see who has it less than 1,2 kg.'

'It is a very difficult moment now: the guys are not familiar with the software of the milling machines, so they'll have to take a risk and play a Russian roulette,' said Komarov.